UMN Respirator Mask Design Projects Led by ME Professors

The need for N95 masks has skyrocketed in recent weeks in response to COVID-19. To address this challenge, an interdisciplinary research team at the University of Minnesota Twin Cities has designed two respirator mask prototypes from donated filter material by Cummins and bendable components from Bedford Industries.

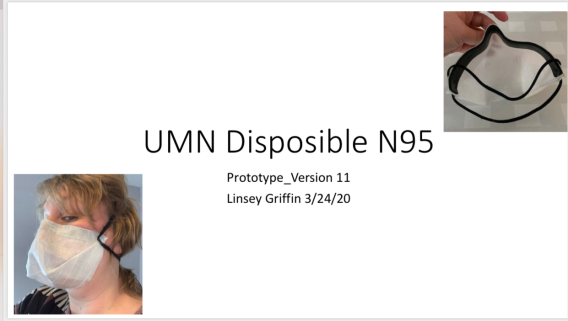

The masks—one modified anesthesia mask and one single-use, disposable mask—are being developed to be close to a N95-equivalent with three distinctive components in mind: ventilation, fit and resilience to supply chain fluctuations.

At the Center for Filtration Research, David Pui and his team were able to test how well the masks would be able to reject virus-containing droplets. His testing results showed that the efficiency of the Cummins material was nearly equivalent to that of filtration material typically found in N95 masks—potentially making the U of M prototypes a viable alternative for health care professionals.

The Institute for Engineering in Medicine (IEM), directed by ME Professor John Bischof, is also testing filtration material to see what alternatives could be implemented that come close to N95 mask standards. "Even the CDC will say something is better than nothing," said Bischof. This is especially true in unusual circumstances, and when the "something" is nearly as effective as the gold standard.