Explore Chemical Engineering

Chemical engineers build a bridge between science and manufacturing, applying the principles of chemistry and engineering to solve problems involving the production or use of chemicals. They design equipment and develop processes for large-scale chemical manufacturing, plan and test methods of manufacturing products and treating byproducts, and supervise production. Chemical engineers also work in a variety of manufacturing industries other than chemical manufacturing, such as those producing electronics, photographic equipment, clothing, and pulp and paper. They also work in the healthcare, biotechnology, and business services industries.

Chemical engineers apply principles of chemistry, physics, mathematics, and mechanical and electrical engineering. They frequently specialize in a particular chemical process such as oxidation or polymerization. Others specialize in a particular field, such as materials science, or in the development of specific products such as fertilizers and pesticides, automotive plastics, or chlorine bleach. They must be aware of all aspects of chemical manufacturing and how it affects the environment, the safety of workers, and the customers. Chemical engineers use computer technology to optimize all phases of research and production, so they need to understand how to apply computer skills to chemical process analysis, automated control systems, and statistical quality control.

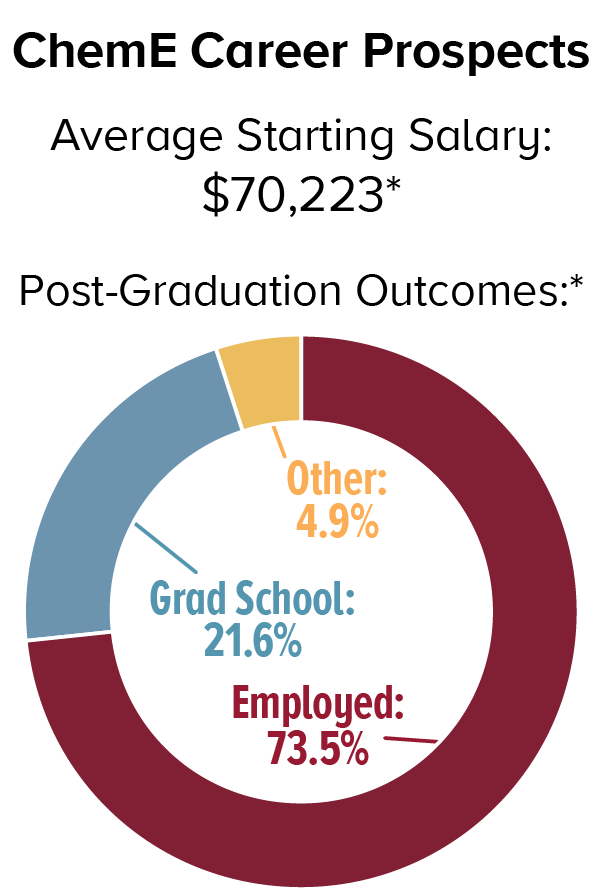

*Salary and Career Outcomes gathered from the 2020-2021 CSE Graduation Survey. Post-graduation outcomes reflect the percentage of students who were employed full-time in their field or were enrolled in a graduate program at 6 months post-graduation.

+

What can I do with a major in Chemical Engineering?

INDUSTRIES

- Agriculture

- Appliance manufacturing

- Biotechnology

- Clothing/textiles

- Consulting

- Food/beverage

- Healthcare

- Higher education

- Industrial products

- Manufacturing

- Mining

- Packaging

- Parts design

- Pest control

- Petroleum

- Pharmaceutical products

- Pharmaceuticals

- Polymer resins

- Pulp and paper

- Tire and rubber

EMPLOYERS

- 3M

- Andersen Corporation

- Boston Scientific

- Brady Corporation

- Cargill

- Ecolab

- Emerson

- Epic Systems

- ExxonMobil

- Flint Hills Resources

- General Electric

- General Mills

- H.B. Fuller

- Kraft Heinz

- Land O’Lakes

- Medtronic

- MOM Brands

- Renewable Energy Group, Inc.

- Schlumberger

- Sherwin Williams

- Stratasys

- The Dow Chemical Company

TECHNICAL SKILLS

- Advanced and Basic Chemistry Laboratory Techniques

- Biology Laboratory Techniques

- ChemDraw

- Excel

- LoggerPro

- Mathematica

- MATLAB

POSSIBLE POSITIONS

- Chemical engineer: Design chemical plant equipment and devise processes for manufacturing chemicals and products by applying principles and technology of chemistry, physics, and engineering.

- Operations and manufacturing engineer: Design, integrate, or improve manufacturing systems and related processes. Spends time ensuring that a plant is producing the right amount of product to the correct specification.

- Process engineer: Designs, implements, controls, and optimizes industrial processes—such as chemical, food, pharmaceutical etc.

- Product engineer: Follows the production cycle of a particular product to ensure it is meeting specification. Product engineers may work with marketing and R&D to ensure that a product will meet the needs of customers, then sees the product through production. They may work on new products or variations of existing products.

- Project engineer: Organizes and runs projects for engineering companies. This can be anything from managing a small modification to an existing pharmaceutical facility to building a multi-billion dollar petrochemicals complex.

- Quality control engineer: Monitors the manufacturing of products to ensure that quality standards are maintained. Quality control engineers may bring samples of a product in from a field test or from a normal application, and then test them to determine how specific properties — such as strength, color, and weatherability — change over time.

- Research and development engineer: Develops the ideas for future plants, improving efficiency, environmental performance, and even developing new products.

- Technical analyst: Works independently and identifies appropriate course of action to analyze issues, recommend solutions, and administer budget.

**Some of these positions may require an advanced degree.

GET INVOLVED

- Active Energy Club

- Alpha Chi Sigma

- American Institute of Chemical Engineers

- CSE K-12 Outreach

- CSE Ambassadors

- CSE International Ambassadors

- Engineers Without Borders

- Nat’l Org for the Professional Advancement of Black Chemists and Chemical Engineers

- National Society of Black Engineers

- Plumb Bob Honorary Leadership Society

- Science and Engineering Student Board

- Society of Asian Scientists and Engineers

- Society of Hispanic Professional Engineers

- Society of Women Engineers

- Solar Vehicle Project

- Tau Beta Pi

- TeslaWorks

- Theta Tau

PDF

+

Q&A with Jackson Baril, Medical Student–Class of 2020, University of Minnesota Medical School

What do you do?

In my first and second years, I learn the science of medicine and spend about one day a week with practice patients or real patients to develop my clinical skills. During my third and fourth years, I will be on the wards in various inpatient and outpatient settings 5-6 days a week.

What's a typical workday?

I will watch 3-4 lectures online, go to a lab course or my clinical skills course for 2-4 hours, study material from previous days, and prepare for exams. I have time to go to the rec center and exercise. I study every weekend and volunteer in three extracurricular organizations. Overall, you are doing about 60 hours per week of school work when you are a first- or second-year medical student.

What qualities are important for this position?

- Resiliency—medical training is long and challenging. You must be resilient and work hard, but also take care of yourself and not burn out.

- Empathy—caring for patients requires that you really care about them as people, even when they appear to have put themselves in their situation, disagree with you, or are from a different background that you.

- Interpersonal communication—if you can't be clear in directing the medical care for your patient, how can you expect a nurse, other physician, or patient to carry out that mission accurately?

- Intellectual curiosity—medicine is incredibly complex. The idea of being a lifelong learner should excite you.

What part of your job is most satisfying?

Accompanying patients on their journey. You get to use your interpersonal skills, as much as your medical knowledge and reasoning, to help patients. For example, I observed a mitral valve replacement on a critically ill patient, and I’ll never forget the look of sheer gratitude and hope on the family’s faces when they heard that the surgery was a success. Solving complex problems and integrating many areas of medical knowledge is akin to solving complex engineering problems. It's very intellectually satisfying!

Most challenging?

It's a long road to become an attending physician. This means years of study, years of practice, and therefore years of delaying certain things in life like buying a house. It can be hard to continue as a student, then resident, while your friends pursue careers and move to different stages of life. You should be content with delayed gratification.

Advice for current students?

Chemical engineering is a fantastic major and I loved it! You go through a rigorous program and become a better student, and person, in the process (plus the material is fascinating). That said, chemical engineering is not a typical major for pre-med because it is so challenging. It can be difficult to fit in the extracurriculars and elective courses you need to apply to medical school. Reflect on your interests and ability to fit in those things that are important in a medical school application when deciding on your major.

Any other advice you'd like to share?

If you’re considering medical school, think about what you would like on your application early in your undergraduate career. If you want research experience, ask the principal investigators or faculty for positions. The worst that will happen is someone will say no. That said, many students apply later in life to medical school too. I highly recommend shadowing physicians, both for your application and your own growth. Take the MCAT seriously and study at least from preparation books and practice exams. Lastly, submit your application early. Most medical schools are rolling admission and the earlier you apply the better.

+

Q&A with Adam Meuler, Senior Technical Superisor, 3M

What do you do?

I supervise and lead a team of 13 full-time researchers developing biomaterial technologies. My team works in 3M’s Corporate Research Materials Laboratory, an organization that is not responsible for any one specific product or business, but is rather tasked with technology development for 3M as a whole. My group operates at the interface between academic research and commercial product development, and is typically trying to take new technologies and figure out how to turn them into commercial products.

In general, our technology development efforts are long-term in nature, and often last more than 3 years until a technology is commercialized. Examples of technologies developed by my team include separation/purification technology for biopharma products, diagnostic and molecular detection technologies, and various materials for the promotion of oral health.

What's a typical work day?

I typically spend a portion of my day in meetings with my team and/or with collaborators in other organizations within 3M. The meetings cover technology development, business or market strategy, and coaching of team members. I also attend and give presentations or seminars on a regular basis. There is also time spent on intellectual property/patents, either reviewing or managing our patent portfolio, or working on drafting new patents. Finally, I spend some of my time looking at external science and technology, either through conference attendance, reading the literature, or meeting with external technical experts.

What qualities are important for this position?

The abilities that are important for a successful supervisor are a bit different than those needed by an individual technical contributor. In the supervisory role, an ability to relate to team members and coach them through their own projects is critically important. Communication skills are critical, both in communicating with my team and in communicating with upper management and/or with colleagues in other parts of 3M (both technical and business).

Successful supervisors/managers need to be able to ask good technical questions, and consequently be able to recognize and champion promising research programs. Patience is also a virtue in supervision. Researchers need time to figure out solutions to the tough technical problems.

What about technical skills?

Supervisors need to be able to understand a broad range of technologies, and be able to quickly pick up and understand technologies in new areas. The latter skill is especially important as one transitions to new groups or technology areas. This ability to learn quick is something I believe I developed during graduate school at the University of Minnesota. Good supervisors have enough technical depth to be able to ask good technical questions and to understand when the team has made a promising discovery. Good supervisors also need to be able to determine when an idea is technically flawed and should be re-scoped.

What training were you offered for your position?

There are many technical seminars at 3M, all of which provide an opportunity to learn something new. In terms of training for a management/supervisory role, I frequently attend courses on leadership and management. Some of these courses are all-day events, while others last a few hours. There is also a lot of individual coaching from more senior managers.

What part of your job is most satisfying?

I perform investigations on new and existing raw materials, provide technical support for production and process control, and facilitate new product development.

What's a typical work day?

Typical days are a mix of meetings, lab/plant work, and desk work. All are important; some days are heavier in one area.

What qualities are important for this position?

Adaptability, positive attitude, and willingness to be part of the solution are most important at Cambria, though I would wager this is universal to all companies. Abilities can be taught, but only to those who want to learn.

What about technical skills?

Strong technical background, spatial awareness, organized and detailed, familiarity with programming and software.

What training were you offered for your position?

Most training at any company is “how to” perform a specific task or run equipment. Best practices for professionalism, time management, and work product come from your undergraduate experience and through self-awareness.

What are your possible career paths now?

There are opportunities to continue along the path of technical management, either within the Corporate Labs or in one of 3M’s commercialization divisions. There are also opportunities to into more business-focused roles (e.g., marketing, business development). Some members of 3M’s senior management team came from the technical labs.

Advice for current students?

Chemical engineering is a great major because you will learn to solve problems. This problem-solving ability and mindset can be readily transferred to new areas outside of the core fundamental technologies associated with chemical engineering. I believe this ability to move into new areas is what makes a chemical engineering degree truly valuable in the marketplace.

Any other advice you'd like to share?

Never stop learning new things.

+

Q&A with Matthew LaBrosse, Senior R&D Engineer, Cambria

What do you do?

I perform investigations on new and existing raw materials, provide technical support for production and process control, and facilitate new product development.

What's a typical work day?

Typical days are a mix of meetings, lab/plant work, and desk work. All are important; some days are heavier in one area.

What qualities are important for this position?

Adaptability, positive attitude, and willingness to be part of the solution are most important at Cambria, though I would wager this is universal to all companies. Abilities can be taught, but only to those who want to learn.

What about technical skills?

Strong technical background, spatial awareness, organized and detailed, familiarity with programming and software.

What training were you offered for your position?

Most training at any company is “how to” perform a specific task or run equipment. Best practices for professionalism, time management, and work product come from your undergraduate experience and through self-awareness.

What part of your job is most satisfying?

I enjoy being a critical piece to the resolution of an issue. Chemical engineers are hired for their broad knowledge base, versatility, and problem-solving abilities.

Most challenging?

Working in teams or groups is a departure from much of the individual work done as an undergraduate. This can still be a challenge, though it gets easier.

What are your possible career paths now?

I am currently at a comfortable position with not much room upward. However, growth comes in other forms. My path forward is to continue expanding my role in the company and building a team to support that vision.

Advice for current students?

The Chemical Engineering program at the University of Minnesota is very difficult and should be selected with care, but it is worth the challenge! Those who successfully complete the program will be armed with broad knowledge base and technical skills to succeed in any industry.

Any other advice you'd like to share?

To me, the goal in selecting a major is finding something in line with your passions, abilities, and future goals.

+

Q&A with Aarti Anand, External Quality Packaging Manager, General Mills

What do you do?

I manage two packaging categories for General Mills' North American plants, working directly with suppliers and our plant leadership to troubleshoot issues, improve capabilities, and reduce losses.

What’s a typical work day?

I spend a lot of time on Skype and the phone, talking to our top suppliers about on-going initiatives and recent issues, and similarly, talking to our plants about trends in what causes them downtime and challenges with the machine-material interface on their automated packaging equipment. I spend the rest of my time traveling directly to manufacturing facilities to audit suppliers or help our plants.

What qualities are important for this position?

It’s important to stay un-emotional and diplomatic. Getting resolution to on-going issues or improving a long-standing process often means removing the need for blame and focusing on facts and data.

What about technical skills?

A quick, intuitive grasp of unit operations is important. The ability to run a design of experiments test to arrive at root cause and use statistics to quantify expected variability is necessary. In working with packaging, I also use much of my material science coursework.

What training were you offered for your position?

We have internal packaging technical experts who offer training on machines and materials we use in our North American facilities. I have also benefited from training delivered directly by our packaging suppliers to learn about their processes and see their manufacturing lines firsthand.

What part of your job is most satisfying?

It is rewarding to me to approach a fraught situation with a neutral, fact-driven approach and to come out the other side with a local plant-vendor relationship that is both stronger and more collaborative.

Most challenging?

General Mills doesn’t make packaging, we make food. Our manufacturing facilities, therefore, do not have a technical background on the materials they run, only what the end product should look like. A large portion of my job is to educate our own facilities and help them understand packaging manufacturing with enough depth to effectively work with suppliers.

What are your possible career paths now?

I began my career at General Mills in an R&D role focused on processing and scale-up of food. Since then, I have gained international processing and packaging experience, and domestic packaging experience. I enjoy working with our plants on engineering problems, so I can see myself deepening my expertise in minimizing losses in manufacturing and growing a career in technology and engineering. Leaders in R&D and Quality, my area, often have engineering backgrounds and many rise to director and VP levels without further degrees.

Advice for current students?

Stick with it. There are courses that you’ll struggle with because the content is tough. But it’s good education for life—and employers value your degree because they know you faced adversity.

Any other advice you'd like to share?

Don't be discouraged if what you are passionate about doing doesn’t seem like a job employers are trying to hire you for. It’s either a job you can have in a few years once you’ve learned about the industry you’re headed into, or it’s one you can create. Express your passion and your vision confidently.

+

Q&A with Leah Dhuria, Senior Product Engineer, Medtronic

What do you do?

Manage 53 suppliers across categories of chemicals, resins, films, tubing, and ceramics. Collaborate with Medtronic’s global suppliers to improve production processes and ensure quality product. Perform external process audits and quality system audits of suppliers to ISO 13485 and ISO 9001 standards.

What’s a typical work day?

Most of my projects are long term. However, since I support manufacturing, I could come in with a lot of pressure to prevent a manufacturing line from going down. This results in extensive project management in a short amount of time with limited resources. There’s a lot of creative thinking processes from improving time and quality with shipping, inspection, and acceptance in the line.

What qualities are important for this position?

You need to be quick on your feet, creative with quick solutions, and a go-getter to get things done.

What about technical skills?

Materials engineering and process engineering are valuable just from an ability to come up with creative solutions and explain them in layman's terms to regulatory bodies, or just downstream customers that may not have the engineering knowledge and background.

What training were you offered for your position?

Mostly on the job training. But you don’t get much time before you’re on your own.

What part of your job is most satisfying?

Every day is different, and the people I work with are great!

Most challenging?

Every day is different, and working in a regulated industry can be frustrating.

What are your possible career paths now?

Sourcing is a growing field in every industry. As regulatory bodies are starting to look at supplier controls, every industry is needing help with how to best handle this. From that I can go into the clothing industry, food industry, pharma industry, etc. and they need experienced managers too, so management is an available track as well.

Advice for current students?

Chemical engineering is broad enough that it applies everywhere.

Any other advice you'd like to share?

You need to like what you do and feel passion for the products you help create. Money isn’t everything. Those who work for just the money will struggle to do their job well.

+

Q&A with Alison Cozad, Optimization Engineer, ExxonMobil

What do you do?

Modeling and optimization support of the mathematical models for planning, scheduling, and process decisions in refining and chemical processes.

What’s a typical work day?

A variety of tasks from creating math models to programming to teaching people about my work to PowerPoint engineering.

What qualities are important for this position?

Analytical skills, persuasion, creativity, negotiation, adaptability

What about technical skills?

Critical thinking, challenging assumptions, process modeling, mathematical modeling, characterization of uncertainty, sensitivity analysis, optimization, IT skills (programming, databases, etc.)

What training were you offered for your position?

I was taught my technology area from the ground up. We were also offered a host of soft skills training: leadership, presentation, and technical writing.

What part of your job is most satisfying?

Teaching colleagues complex topics

Most challenging?

Writing emails

What are your possible career paths now?

We have two tracks: technical and managerial. Promotion opportunities for both tracks can reach executive levels.

Advice for current students?

Take interesting classes outside your field.

Any other advice you'd like to share?

Find ways to learn and show leadership skills in student groups, internships, and other activities.

+

Q&A with Xin Ru (Ruby) Han, Reliability Engineer, Schlumberger

What do you do?

Troubleshoot frac equipment failures and work on reliability, continuous improvement projects.

What’s a typical work day?

Failure investigations and training modules.

What qualities are important for this position?

Interpersonal skills and being organized, managing workload efficiently.

What about technical skills?

Knowledgeable in hydraulic, pheimatic and electrical systems.

What training were you offered for your position?

Fixed step training—operation schools, equipment schools, field training

What part of your job is most satisfying?

Traveling for work.

Most challenging?

Finding the root cause for equipment failures.

What are your possible career paths now?

Managerial roles

Advice for current students?

If you’re passionate about the major you’re in, go for it.

Any other advice you'd like to share?

Tough times don’t last, only tough people do.

+

Q&A with Zach Jaeger, Engineering Specialist, FM Global

What do you do?

Partner with FM Global clients to identify and evaluate hazards at their facility and provide engineering solutions to mitigate or reduce the exposures to their business.

What’s a typical work day?

A typical day involves visiting a client facility such as a complex chemical plant or paper mill to consult and help FM Global clients manage hazards and risks at their facility.

What qualities are important for this position?

Strong skills in communication, problem solving and technical writing, while being willing to collaborate and work alongside other team members of varying backgrounds, expertise and functions.

What about technical skills?

Strong skills in engineering problem solving, technical writing and attention to detail.

What training were you offered for your position?

Extensive classroom, hands-on and on-the-job onboard training, along with continuing/ongoing education in various advanced topics and specialties.

What part of your job is most satisfying?

I enjoy helping clients protect the value of their business, working towards preventing hazards at their facility from interrupting the business that many depend on for employment, products, services, etc.

Most challenging?

Learning new, complex processes and identifying which risks will most impact a client.

What are your possible career paths now?

There are several career paths and opportunities, including account engineering/management, underwriting, claims, training, research and more.

Advice for current students

Chemical engineering may be the major for you if you are looking for a field with incredibly diverse career opportunities, including product and process research and development, process design, process operations, process safety and risk, and more.

Any other advice you'd like to share?

Chemical engineering is a challenging and rewarding field with diverse employment opportunities available. So if it sounds interesting, go for it!

+

Q&A with Andrew Jones, CEO and Co-founder, Activated Research Company

What do you do?

Operations, research and development, sales, support

What’s a typical work day?

Every day is truly different. From meeting with customers to designing a new catalyst or reactor.

What qualities are important for this position?

Perseverance, tenacity, passion, people skills, empathy, multi-disciplined skillset

What about technical skills?

Transport, catalysis, heat and mass transfer, coding, modeling, project planning, experimental design, teamwork

What part of your job is most satisfying?

Learning from customers about how your innovations have changed their lives

Most challenging?

Marketing and sales

What are your possible career paths now?

Company growth

Advice for current students?

Chemical engineering is an excellent degree because of the diversity of skills and knowledge that students are exposed to. It provides an excellent foundation for learning.

Any other advice you'd like to share?

There are lots of great startups looking for passionate people. Search them out and get a job with one, it will be a great experience regardless of whether it succeeds or fails.