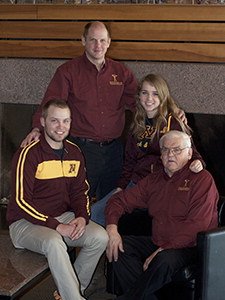

The Cabak Family

Jim Cabak, Sr., (ME ’60) was about 12 when his older brother Michael enrolled in engineering at the University of Minnesota. “My brother’s pretty smart,” he remembers. He wondered, “I don’t know why he wants to drive a train.”

Soon enough, he learned about engineering. Growing up on a farm near Hinckley, Minn., Cabak had many opportunities to exercise his mechanical aptitude. He enrolled in engineering in 1955. But his big dream, as a high school football player, was to try out for the University of Minnesota Gopher football team. “I walked on for about two days. I found out right away that it wasn’t the place for me,” Cabak said. “Too big? Too fast? All of the above.”

So, he buckled down to studying mechanical engineering and struggled, as many engineering majors do to this day, with math and science. He took advantage of the co-op program (when the University operated on quarters and engineering took five years). Interning at Ford Motor Company in Detroit, he was shown a room the size of a football field filled with engineers at drafting tables. “I learned a lot at Ford,” he said. “The main thing I learned is that I really didn’t want to be a drawing board engineer. I figured I’d get lost out there.”

After graduation, Cabak took two quarters of University business classes. He says it was a reaction to Ford. “You’ve got to know more than engineering unless you want to live on that farm the rest of your life,” he said.

“I feel CSE did a great job of preparing me for working in industry. I would recommend it to any one of my friends or future family members.”--Matt Rontti

He went to work for General Mills, setting up packaging lines. After five years, he decided to try sales, where he thought he saw more opportunity. But he didn’t want to sell Cheerios. So he moved to Chicago to work for a company that built packaging machinery. After five years, he moved to another company, selling processing equipment. There he learned about injectable thermosetting plastics. “I thought I could do that without too much trouble,” he said.

As it was, his neighbor worked in an industry that used the material, and the two men formed a business to make molded plastic products. That was the beginning of Bulk Molding Compounds, Inc., a company Cabak would grow to about 75 employees and nearly $20 million in annual sales before selling it in 1989. Since then, he has been involved in other small companies, investing or serving on boards.

Cabak says his engineering degree helped him to understand systems. “Aside from the details of engineering, it gave me the ability to understand an entire manufacturing or processing operation,” he said. “It certainly was very helpful to me when I started BMC.”

At the same time, the two quarters of business coursework broadened his perspective. “It provided me with an understanding of accounting and what you have to do to make a project successful. The old cliché of you build a better product and the world will beat a path to your door really isn’t true. You’ve got to know how to market it. Most people don’t come looking for a product. You’ve got to bring it to them,” he said.

Jim Jr. follows father’s footsteps

For Jim Cabak’s son, Jim Jr., the fact that his dad was an engineer “helped a lot.” He followed in his father’s footsteps, enrolling in the University’s mechanical engineering program. Beside the family tradition of maroon and gold, the University offered more than smaller schools. “That’s the advantage of a big university—the big schools have the resources or access to whatever you need,” he said. He received his degree in 1989 and went to work for American Medical Systems, a company that made implants for incontinence and impotence. Cabak was fascinated by engineering solutions to medical problems. “It was fun to actually apply the skills you learned.”

But he wanted to learn more, especially on the medical side. He decided to pursue a master’s in biomedical engineering. “The biomed was so different from the mechanical,” said Cabak. “I really enjoyed that.”

Cabak took a chance and left for Boston Scientific, and then Medtronic. Finally, he went to Uromedica, a small company in Plymouth, Minn. founded by former American Medical Systems employees. The company sells devices for urinary incontinence but only in Europe as it awaits FDA approval to sell in the United States. Cabak is the director of research and development and operations. “Since we’re small, I have to do it all,” he said. “One of the things I’ve learned is at a big company you can do a lot in a small area. In a small company, you get to do a lot of everything.”

Like grandfather and uncle

Matt Rontti (ME ’12)—Jim Cabak, Sr.’s grandson and Jim Cabak Jr.’s nephew— credits his grandfather for sparking his interest in engineering. “Mathematics was always my strongest subject in high school, followed by the sciences,” said Rontti. “However, I remember visiting the mechanical engineering building and labs on the Minneapolis campus with my grandfather when I was young. I think that may have influenced my decision to attend the University of Minnesota because it was the only college I applied to. I never looked elsewhere.”

He also was drawn to the urban atmosphere, after growing up in Elk River, Minn. “I liked being close to the city, where major attractions were so convenient,” he said.

Like his grandfather and uncle before him, Rontti majored in mechanical engineering, which was his first choice. “It seemed like a natural and logical fit,” Rontti said.

As a student, Rontti participated in the Engineering Co-op Program at PaR Systems, Inc. in Shoreview, Minn. where he is now employed full-time as a mechanical engineer. Similar to an internship, the co-op experience provides valuable work experience during the last two years of a student’s academic career, and gives them an opportunity to apply some of their knowledge of fundamental theory to practical problem solving. Students also earn credits toward their degree program.

Rontti says he enjoys his position where he works on 3D CAD (computer-aided design) modeling for large-scale robotic applications. He is also looking into earning an advanced degree, perhaps an MBA or Management of Technology degree through CSE.

“I feel CSE did a great job of preparing me for working in industry,” Rontti said. “I would recommend it to any one of my friends or future family members.”

The next generation

Continuing the family’s engineering tradition is Melissa Cabak, Jim Jr.’s daughter. A sophomore in chemical engineering, she also competes for the University in women’s cross-country and track and field. She attributes her interest in engineering at least in part to watching her dad. “Because my dad works at a small company, I’ve been able to go in and see exactly what he does at a level I wouldn’t be able to do if he worked in a large company,” she said.

She likes science but is drawn to engineering for its practicality. “I have always been pretty good at math and science, but the appeal of engineering rather than a straight up chemistry degree is probably that I enjoy the application,” she said. “I’d rather have the whole knowledge base and get to go ahead and apply what I learned.”