CSE Shop equipment

At the CSE Shop, we have an inventory of machines on hand that will allow us to make many different types of parts that are requested. Our most often requested capabilities include CNC milling and turning, wire EDM machining, welding and abrasive water jet cutting.

Check out the various equipment in the CSE Shop below.

+

Milling

We have an array of milling machines from Haas, Milltronics, Southwest Industries and Bridgeport ranging from manual machines to 3- and 4-axis CNC machines capable of handling part sizes up to 1500 x 760 x 700 mm.

+

Turning

There are both manual and CNC lathes in the shop that can handle parts both small and large. Depending on whether you need one part or 100, we should have a lathe that can be used for your project.

+

Electrical Discharge Machining (EDM)

The CSE Shop has two wire EDM machines (WEDM) that are able to cut through virtually any material that is conductive up to ~200mm thick. They typically use a 0.25mm wire to cut the material so small, detailed features can be created. We also have an EDM drill that can be used to put non-precision holes in the same materials that can be cut by the WEDM.

+

Abrasive Water Jet Cutting

One of the machine tools most often used in the shop is the Flow International Mach 2c abrasive water jet which has a cutting area of 2m x 2m. It can cut through most materials up to 125mm thick with a typical accuracy of +/-0.2mm (depending on thickness).

+

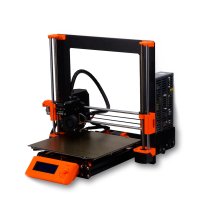

3D printing

The CSE Shop has a Prusa i3 MK3S+ 3D printer for printing plastic parts either for end use or prototyping purposes. It is a basic printer with a 250 x 210 x 210mm build volume.

+

Miscellaneous Cutting and Sawing

For cutting and sawing a variety of materials, the CSE Shop has machines such as vertical and horizontal band saws, an Epilog 18” x 24” laser cutter/engraver, a Buehler Isomet low speed diamond saw for cutting small diameter glass, quartz or other ceramic tubes and rods, and various other power tools like a table saw and a miter saw.

+

Sheet Metal and Tubing

The CSE Shop has a fairly limited range of tools used to make sheetmetal or parts or enclosures. Some of the equipment we do have is a 50” hydraulic sheet metal shear for thin gauge materials, various manual bending equipment like a pan brake, a box brake, and a Di-Acro manual bender.

+

Inspection

The CSE Shop has a nicely equipped inspection area is used to ensure the quality of our work. Inspection equipment ranges from gage blocks and micrometers to a CNC Zeiss Coordinate Measuring Machine, a QVI Sprint video measurement machine, and an Alcatel helium leak detector (not available for loan).