New innovation labs turn students' ideas into reality

Space includes waterjet cutter, computer-controlled milling machines, and the largest bank of 3D printers on campus

Innovative. Creative. Entrepreneurial. These all describe University of Minnesota College of Science and Engineering (CSE) students, and now with the right tools and space, their ideas can become reality.

Thanks to a generous donation from Clifford I. (BSB ’62) and Nancy C. Anderson and the vision of former CSE Dean Steven L. Crouch, the college is opening three new student innovation labs on campus during fall 2016—two labs are new and one is a major upgrade. All will have state-of-the-art equipment and space for student group projects, design and capstone course projects, and student entrepreneurs.

The three new spaces, named the Anderson Student Innovation Labs in honor of the donors, add more than 10,000 square feet of hands-on learning space for students. When added to existing student shop spaces on campus, the new labs bring the University of Minnesota College of Science and Engineering in line with the experiential learning space provided by other top universities across the country.

“As soon as a student sees the equipment and space, their eyes light up and they say ‘Wow! This is our space?’ You can almost see their brains working on what they can build,” said Will Durfee, a mechanical engineering professor who led the CSE Student Shops Committee of faculty, staff and students.

That spirit of innovation and creativity is precisely what the donors wanted.

“We want this to be a place for those who need to see if their imaginations lead to reality,” said Clifford Anderson.

Clifford and Nancy Anderson have donated to several experiential learning projects within CSE.

State-of-the art equipment

Two of the Anderson Student Innovation Labs are located in the Mechanical Engineering Building and one is in the Civil Engineering Building. All three spaces will be available to students throughout the college.

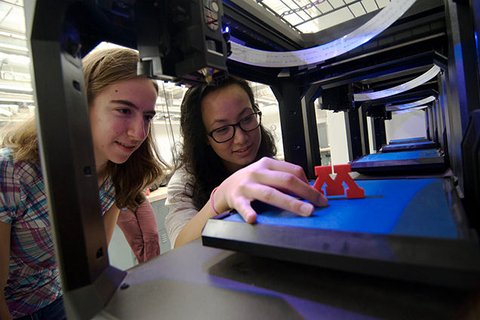

The largest of the new innovation labs is about 5,000 square feet in Mechanical Engineering, Room 2134 and was designed primarily for prototyping. This space includes four laser cutters where students can cut wood, plastic and cardboard into all kinds of shapes. It also includes 20 3D printers, making it the largest 3D printing facility on campus.

Sixteen of the 3D printers are do-it-yourself printers that students can use to create parts and prototypes for their student group project or class. Four of the 3D printers are high-end 3D printers for more precision projects. Twelve large work benches, computer lab space, a tool lending library, and large assembly areas for mechanical and electrical projects are just a few of the other features of the space. All areas of the lab are wheelchair accessible and large windows provide an “innovation on display” feeling throughout the building.

The second space of about 2,000 square feet in Mechanical Engineering, Room 176 upgrades a traditional machine shop with top-of-the line equipment. In addition to a full complement of metal working mills, lathes and band saws, the college purchased two computer-controlled milling machines, a computer-controlled lathe, and a waterjet cutter.

“It’s exciting because students will now have access to the same equipment quality and brands they will see in industry,” Durfee said. “We could have never afforded this expensive equipment without the donation.”

The third innovation lab of nearly 3,000 square feet in the Civil Engineering Building will include additional 3D printers, a 3D scanner for digitizing objects, a materials testing load frame, welding facilities, and a comprehensive collection of woodworking tools.

Turning ideas into reality

“In the classroom you learn about the various components for things and make sketches, but you really don’t know if things are going to work until you actually build them,” said Jeremy Lund, a third-year mechanical engineering student and student worker in the new innovation labs.

“These new spaces provide access to build things we could have never built before,” Lund said.

Durfee said the Anderson Student Innovation Labs also prepare students for life after college. “Many companies want students who have hands-on experience building things because it is important for engineers to realize their designs,” Durfee said. “Now, our space and equipment dedicated to hands-on learning meets students’ needs.”

If you'd like to support student experiential learning, visit our CSE giving page.