50,000 masks and counting

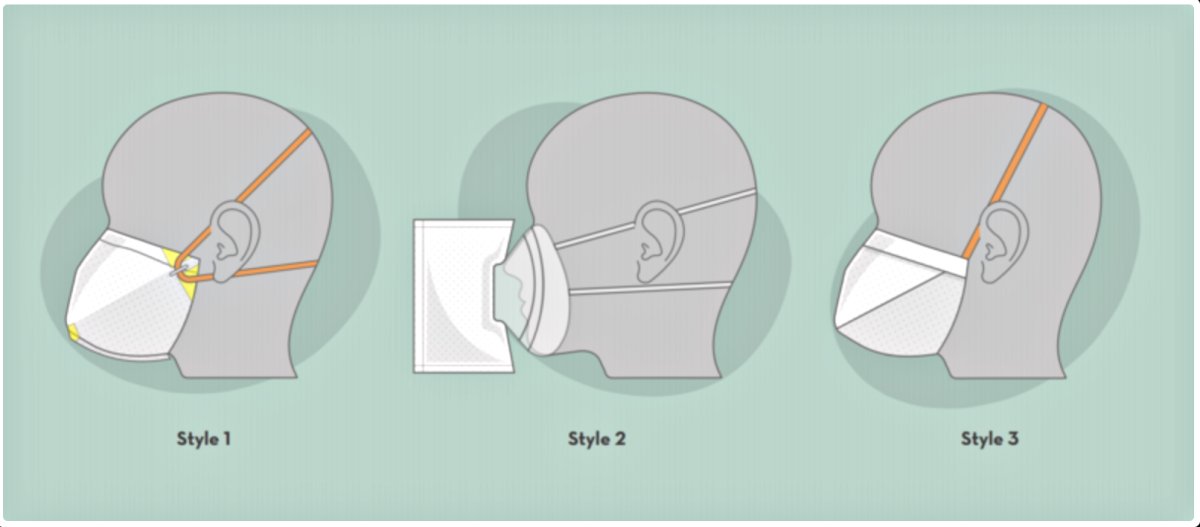

Above: The MNmask Style 3 kit contains components to easily construct 100 general-purpose face masks.

Photo credit: Ben Guengerich

Recent graduate leads volunteer mask-kit assembly in Anderson Labs

June 25, 2020

May was a good month for Laura Bartels. The University of Minnesota College of Science and Engineering student earned her master’s degree in mechanical engineering. She was also recruited to help assemble 500 kits—each with 100 general-purpose face masks from the MNMask project.

“Professor [Will] Durfee asked what my plans were for after school,” Bartels said. “And when I told him the company that hired me had delayed my start date because of the pandemic, he reached out to ask if I would be interested in being part of a mask-making project.”

Durfee, a faculty member and the director of design education in the Department of Mechanical Engineering, is one of many researchers on the Twin Cities campus who collaborated this spring on three emergency-use face masks. The end result—called the MNMask—is a design package for three styles. The project is funded by the University of Minnesota Institute for Engineering in Medicine.

Production began last month in McNeal Hall, with volunteers building 6,000 Style 1 masks. This face mask features a heat-sealed contour, foam for comfort and fit, and versatile band placement for a complete seal. It was delivered to M Health Fairview for use as a crisis stockpile.

That was followed by about 400 Style 2 masks—a reusable anesthesia mask with an attached disposable filter—coming together over two work sessions at the Clifford I. and Nancy C. Anderson Student Innovation Labs in the Mechanical Engineering Building. Ben Guengerich, Anderson Labs manager, directed that effort with mostly undergraduate student volunteers.

Last Wednesday, an assembly line for Style 3 took shape. This general-purpose face mask, whose design was led by College of Science and Engineering Professor Rhonda Franklin, can be built using only a pair of scissors, a ruler, and a stapler.

And that’s where Bartels comes in.

Cake boxes and more

Bartels—a recipient of multiple financial awards from the college including the Robin and Barbara Schaller Scholarship, the Robert E. and Elaine S. Larson Scholarship, and the CSE Alumni Scholarship—was responsible for recruiting volunteers and supervising the process of putting together 50,000 Style 3 masks into hundreds of cake boxes.

“I jumped at the chance to do this,” she said. “Since my full-time position was pushed back to the fall, I had the whole summer with no plans. And I’m glad to do what I can to help give people the PPE [personal protective equipment] they need.”

There were 15 volunteers in total—a mix of undergrads, grad students, and University of Minnesota employees. Each person signed up for two shifts, and each five-hour work shift in Anderson Labs had plenty of breaks plus only three to four people to maintain safe physical distancing.

“When Professor Durfee told me about the project, [500 kits] didn’t sound like much to me,” Bartels recalled. “And then when it was all built, I realized that was an overwhelming amount.”

Not only did she and her volunteers have to sort out all the materials required for each mask from several different bags, they had to unfold 500 cake boxes that had arrived flat and meticulously count the correct number of rubber bands, card-stock rulers (to measure where your staples go), filter sheets, and nose bridges for each kit.

“We had great volunteers,” said Bartels, who also received awards from CSE’s Frank Louk Scholarship Endowment and ME Scholarship Fund.

“It was pretty cool to see all these people coming together to help,” she added. “A few people came alone; a few came in pairs. We wouldn’t have been able to do this without them.”

Although this wasn’t the summer she expected, this is an experience the recent College of Science and Engineering graduate won’t forget.

“It was tedious work,” she said, “but I’m really glad to do what I can during this pandemic. It’s so satisfying to see this giant stack of cake boxes all ready and full of face mask material for those who need it.”

The kits will be distributed, upon request, to interested academic units on the University of Minnesota’s Twin Cities campus.

To request a kit, email mnmask@umn.edu.

Learn more about the MNmask, and download designs, on the UMN Institute for Engineering in Medicine website or UMN Technology Commercialization licensing webpage.

Story by Pauline Oo

If you'd like to support this work and other COVID-19-related activities, visit the CSE Response Fund.