Promising polymers

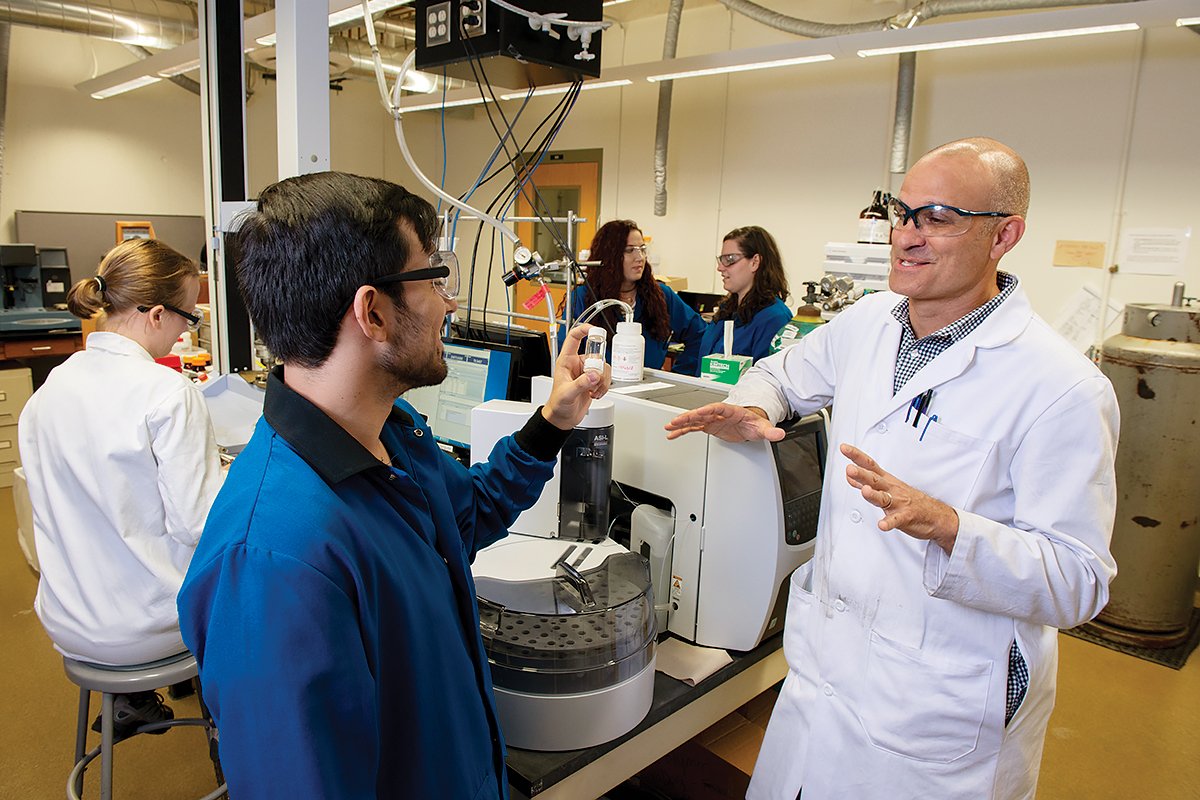

Researchers at the Center for Sustainable Polymers refining the next generation of plastics

November 9, 2018

Here’s the problem with plastics—they’re strong, durable, and convenient. Doesn’t sound like a problem, does it? But because of those qualities, plastics are ubiquitous and hang around forever. Unfortunately, much of it ends up in our waterways or circling endlessly in mid-oceanic gyres.

Marine animals become entangled in this persistent trash and even choke on it. Sea birds on Lord Howe Island near Australia were discovered to be so filled with plastic they couldn’t eat. A sperm whale that washed ashore in Spain was packed with 64 pounds of plastic.

“The durability of plastics is both their strong suit and their Achilles’ heel,” said chemistry professor Marc Hillmyer, director of the University of Minnesota Center for Sustainable Polymers.

Hillmyer and his students are determined to develop new polymers that can serve an environmentally sustainable economy and solve some of the water pollution concerns that plastics themselves currently create.

Most plastic is derived from petroleum—five to 10 percent of the oil we pump from the ground is used for plastic. The first complication is that the oil feedstock itself is not renewable. The second is that these petroleum-based materials, while durable, are difficult to recycle and take nearly forever to break down in the environment.

At the Center for Sustainable Polymers, researchers are discovering and refining renewable raw materials—such as plant-derived sugars and oils—for durable plastics that will be easily recycled or even composted when we’re done with them so they don’t end up in lakes, rivers, and oceans.

“If you start from corn or some plant and you turn it into a degradable plastic, when it biodegrades it turns back into carbon dioxide and water, which are the building blocks for the plant. That’s related to the circular economy idea,” said Hillmyer, also a McKnight Presidential Endowed Chair and Distinguished University Teaching Professor.

“This is a big challenge in our field,” he added, “and it’s going to take the modern tools of chemistry to solve that challenge.”

New ways to make polymer

The center is making progress on several fronts.

For example, renewable polymers being developed there can boost the recycling rate of plastics. (Less than 10 percent of plastic that has ever been produced has been recycled.) A big worry is the mixing of incompatible plastics in consumer recycling. The new polymers help blend the disparate plastics into a usable product.

A second class of new renewable polymers are stretchy “elastomers” that perform just as well as petroleum- based products and could be useful for rubber bands, gaskets, clothing, and sporting goods but can be composted.

The center is also developing bio-based foams, such as those found in chair cushions, that can replace oil-based products. In addition to making plastics easier to recycle, Hillmyer and his students are finding new ways to make polymers (i.e., the molecules of plastics) that can help the environment.

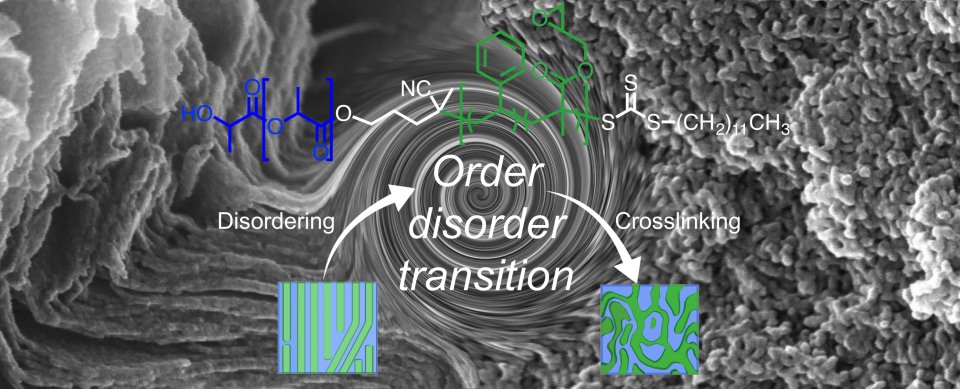

For example, postdoctoral fellow Thomas Vidil and Nicholas Hampu, a graduate student in the Department of Chemical Engineering and Materials Science, engineered “block polymer” molecules to self-assemble into a membrane full of holes that are only about 10 nanometers across—smaller than most viruses.

Vidil and Hampu used a process called the order-disorder transition to create a membrane with uniformly tiny passages from one side to the other that is both highly permeable but also effective in trapping small particles.

The result is an efficient nanoporous “ultrafilteration membrane” that could be more effective than present-day commercial water filters.

“It acts as a colander for very small things,” Hillmyer said.

“Our basic research efforts have allowed us to move the science in a direction that we think will allow us to efficiently manufacture these,” he said. “That’s where the research is still ongoing.”

With further development, such a polymer filter might be used to filter drinking water—in something as compact as a hand-held pump for camping or as large as a municipal water system. It might also be used in wastewater treatment, to filter out bacteria, heavy metals, and even chemical toxins.

“We’re looking for both industrial partners and research grants to be able to continue to push the fundamental science to a point where we’re confident we can go into a development or manufacturing stage,” Hillmyer explained.

Hillmyer said scientists have an obligation to develop new plastics to solve water pollution concerns because, while water is vital to a modern society, so are plastics.

“We’re not going to get rid of plastics anytime soon,” he noted. “I see the research that we’re doing contributing in a positive way to sustainability issues.”

Learn more about the University of Minnesota Center for Sustainable Polymers at csp.umn.edu

Story by Greg Breining

If you’d like to support faculty research, visit our CSE giving page.