3D printing service

If our fleet of DIY printers won’t cut it for your prototyping needs, never fear; we’ve got you covered with our high quality 3D printing service! Below, you’ll find information about the machines, 3D printing technologies, and materials available. When you’re ready to print, simply submit your parts via the online submission form and we’ll notify you when your parts are finished.

Disclaimers:

- This service costs money to use. At this time, we can only accept Gopher Gold and EFS strings for internal UMN-affiliated customers.

- We are not a professional job shop, and we don’t do rush orders! Our typical turnaround time depends on how many parts are in the print queue, staffing, time of year, your part requirements, etc. It's reasonable to expect your parts back within a week. If you need a rush order, use one of the many online print houses instead (xometry, shapeways, protolabs, etc.).

Rules

- If you upload files without specifying that you need a cost estimate, your parts will be printed, and you will be charged for them.

- There is no skipping the queue. We will email you when your part is finished. Parts are printed in the order they are received. Please submit your print request according to your project schedule. Large or complicated parts can take multiple days to print, so lead times vary considerably and unexpectedly depending on demand. Generally, we can produce one big part per day.

- Geometry plays an important role in print quality. Use the design guides on the right to design parts for our 3D printers. If you design parts that are not within these specifications and they fail to print, we are not responsible, and you must still pay for the material you use.

Price list

*Prices are subject to change

+

F170 ASA

$2.48 per cubic inch of model material + $4.46 per cubic inch of support material + $1.16 per print

+

F170 TPU

$2.32 per cubic inch of model material + $4.46 per cubic inch of support material + $1.16 per print

+

Mark Two Onyx

$0.25 per cubic centimeter

+

Mark Two Carbon Fiber Continuous Fiber

$3.00 per cubic centimeter

+

Mark Two Kevlar Continuous Fiber

$2.00 per cubic centimeter

+

Mark Two HSHT Fiberglass Continuous Fiber

$2.00 per cubic centimeter

+

Objet500 Connex3 VeroBlack Plus

$0.15 per gram (Roughly $0.18 per cubic centimeter) + $0.07 per gram of support material (Roughly $0.08 per cubic centimeter) + $1.50 per print

+

Objet500 Connex3 VeroClear

$0.18 per gram (Roughly $0.21 per cubic centimeter) + $0.07 per gram of support material (Roughly $0.08 per cubic centimeter) + $1.50 per print

+

Objet500 Connex3 Clear Agilus 30

$0.19 per gram (Roughly $0.22 per cubic centimeter) + $0.07 per gram of support material (Roughly $0.08 per cubic centimeter) + $1.50 per print

Printer specifications

+

F170 machines

The F170 machines use Fused Deposition Modeling (FDM) technology and have a dedicated soluble support material extruder that allows you to print complex geometry or moving assemblies. There are two material options:

ASA

Matches or exceeds ABS mechanical properties in many areas. UV resistant. Good for general prototyping and for parts meant to be used outdoors. For more information, view the ASA data sheet.

TPU

Flexible material with Shore hardness 92A. For more information, view the TPU data sheet.

+

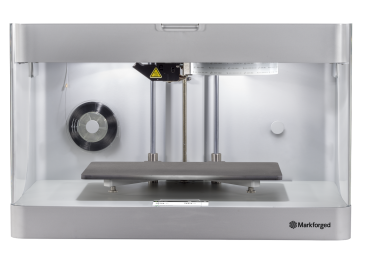

Mark Two machine

The Mark Two machine combines Fused Deposition Modeling (FDM) technology with continuous fiber reinforcement to produce composite parts as strong as aluminum. Parts from this machine are very light and rigid compared to other printing methods. There are four material options:

Onyx Filament

Nylon mixed with chopped carbon fiber. High strength, heat resistance, and chemical resistance. For more information, view the composite materials data sheet.

Carbon Fiber Continuous Fiber

Stiffest fiber reinforcement option with high strength-to-weight ratio. For more information, view the composite materials data sheet.

Kevlar Continuous Fiber

Lightweight and high impact resistance. For more information, view the composite materials data sheet.

HSHT Fiberglass Continuous Fiber

High impact and heat resistance. For more information, view the composite materials data sheet.

Note: If you want to use fiber reinforcement on the Mark Two printer, we will email you to set up a consultation after you submit your parts. There are lots of options to customize your parts with fiber reinforcement, so we want to meet with you to make sure we print your parts the way you need them.

+

Objet500 Connex3 machine

The Objet500 Connex3 uses Polyjet technology to create incredibly detailed multi-material parts. High resolution print heads in the machine jet tiny droplets of resin onto the build plate, and then a UV light passes over the liquid to cure it. The print heads can mix the materials in different ratios to create “digital” materials with unique properties and a range of colors. There are currently four material options:

Agilus 30 Clear

Flexible material with shore hardness of 30-35A. For more information, view the Agilus 30 material data sheet.

VeroBlack Plus

Rigid black material. For more information, view the Vero material data sheet.

VeroClear

Rigid clear material. For more information, view the Vero Clear material data sheet.

Sup 706B

Soluble support material.