CSE startup Innotronics delivers tech research to market

Photo credit: Benjamin Klaver

Mechanical engineering research leads to industry commercialization

November 22, 2021

Rajesh Rajamani develops sensor technology to make machines smarter. Most recently, the College of Science and Engineering professor’s lab in the Department of Mechanical Engineering designed a sensor for cars that uses magnetic fields to estimate the positions of other nearby cars and detect imminent collisions. Now, Rajamani’s startup company Innotronics is using that same sensor technology to detect the position of actuators that help machines move.

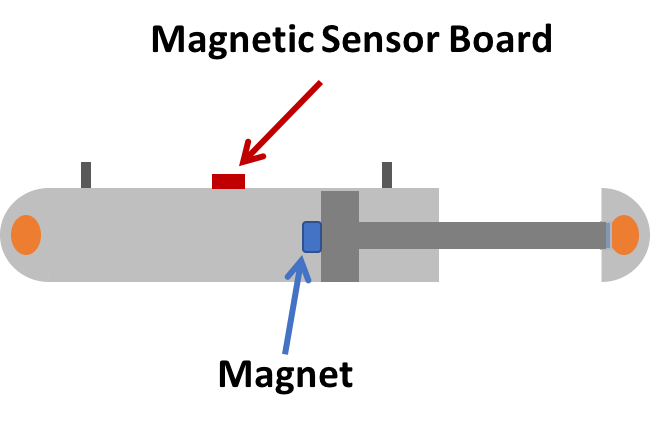

Actuators are present in most machines, especially cars, boats, and agricultural and construction vehicles. They’re responsible for initiating movement. For example, when you press the gas pedal in your car, a sensor sends a signal to an actuator that makes the car move forward. Typically, these sensors must be physically touching the piston on an actuator—but, this decreases the durability of the sensor and makes it prone to wear and tear.

“Contacting sensors tend to break down over time,” explained Rajamani, who holds the Benjamin Y.H. Liu / TSI Applied Technology Chair in Mechanical Engineering. “For example, LVDTs, which are very accurate position sensors, are significantly more expensive, yet they break very easily under shear loads. Non-contacting sensors like ours are going to essentially survive much longer. They don't really have any moving parts, and because of that, they are much more reliable.”

The Innotronics sensor, which is also more cost-effective than other types of position sensors, was recently licensed by Fortune 500 company Parker Hannifin and is now being used on MasterCraft boats optioned with the company's new SurfStar system. The sensor is built into SurfStar’s actuators to allow for greater precision, consistency, and control of the wave height and shape, allowing MasterCraft to deliver easily customizable surf waves for its consumers to enjoy on the water behind their boat.

Innotronics’ success is no small feat, according to Rick Huebsch, executive director of the University of Minnesota’s Technology Commercialization, a division of the Office of the Vice President for Research. Only a fraction—five percent or less—of inventions developed at U.S. research institutions end up making it all the way to commercialization.

The story behind the startup

Rajamani started Innotronics back in 2015 with Mike Gust, with the help of funding from a University of Minnesota MnDRIVE entrepreneurial grant. At the time, Gust—an engineering industry veteran—was the director of industrial relations at the University of Minnesota's Center for Compact and Efficient Fluid Power (CCEFP), a National Science Foundation-funded research facility that brings together academia and industry.

Gust learned about Rajamani’s technology while leading an industry tour of various CCEFP labs on the Twin Cities campus to an outside company.

“I remember a student was describing a research project and said they were using Professor Rajamani’s new sensing technology to determine piston position through the cylinder wall of a prototype engine,” Gust recalled. “As he started to move on, I said, “Hey, wait a minute, I’ve been looking for something like this my whole life! You should start a company and commercialize it. Little did I realize that I would be part of doing so.”

“But one of the reasons I came to the University was to be part of a startup company, and there’s no better place to do a startup than at the University. There’s a lot of infrastructure, young minds, and smart people with brilliant ideas.”

So, Rajamani and Gust worked with UMN colleagues in Tech Commercialization to make it happen. A few years later, they sublicensed the sensor technology to Parker Hannifin for use in non-ferrous or non-steel actuators.

“The CCEFP conference created the dialogue between us and the University on how to leverage this new, non-contact sensor in the hydraulics industry through our Electro Hydraulic Actuators (EHA’s),” said Paul Kubinski, division engineering manager at HPS Parker Hannifin. “With the addition of the Innotronics sensor, our EHA’s functionality increased and created a great opportunity for use in wake boats. Now without the high-cost and reliability limitations of other position sensor technologies, it’s just a question of what other applications the Innotronics sensor can be used for in the future.”

According to Gust, the Innotronics technology hits the three biggest needs of the industrial sensor market: it’s accurate, it’s durable, and it’s cost-effective.

“Every time I bring it up with industry companies they’re immediately interested and want to know more,” Gust said. “It actually sells itself!”

Plus, it directly impacts Minnesota, which is home to an avid wakesurfing community.

“I think this is a win-win-win situation,” Gust said. “It’s good for the University because it says ‘Hey, the University is doing relevant research and helping the community.’ It’s good for Innotronics because we can point to it and say, ‘Look at this cool thing we made.’ And it’s good business for Parker Hannifin. Everything—robots, cars, medical technology—needs sensing. It’s a big market, and it’s going to be much bigger going forward.”

The team is now focused on validating the technology for use on ferrous actuators, or devices that are made of steel, which are used in many heavy machinery, manufacturing, agricultural, and construction applications.

To learn more about how Innotronics’ sensor is being utilized, watch a video about MasterCraft’s new SurfStar technology.

Story by Olivia Hultgren

If you’d like to support research in the University of Minnesota College of Science and Engineering, visit our CSE Giving website.