Sustainable Materials

Everything under the sun

Imagine working in an office building with floor-to-ceiling windows. You may not even notice, but the windows separating you from the outside world are also powering the electricity inside the building—through invisible solar cells in the glass.

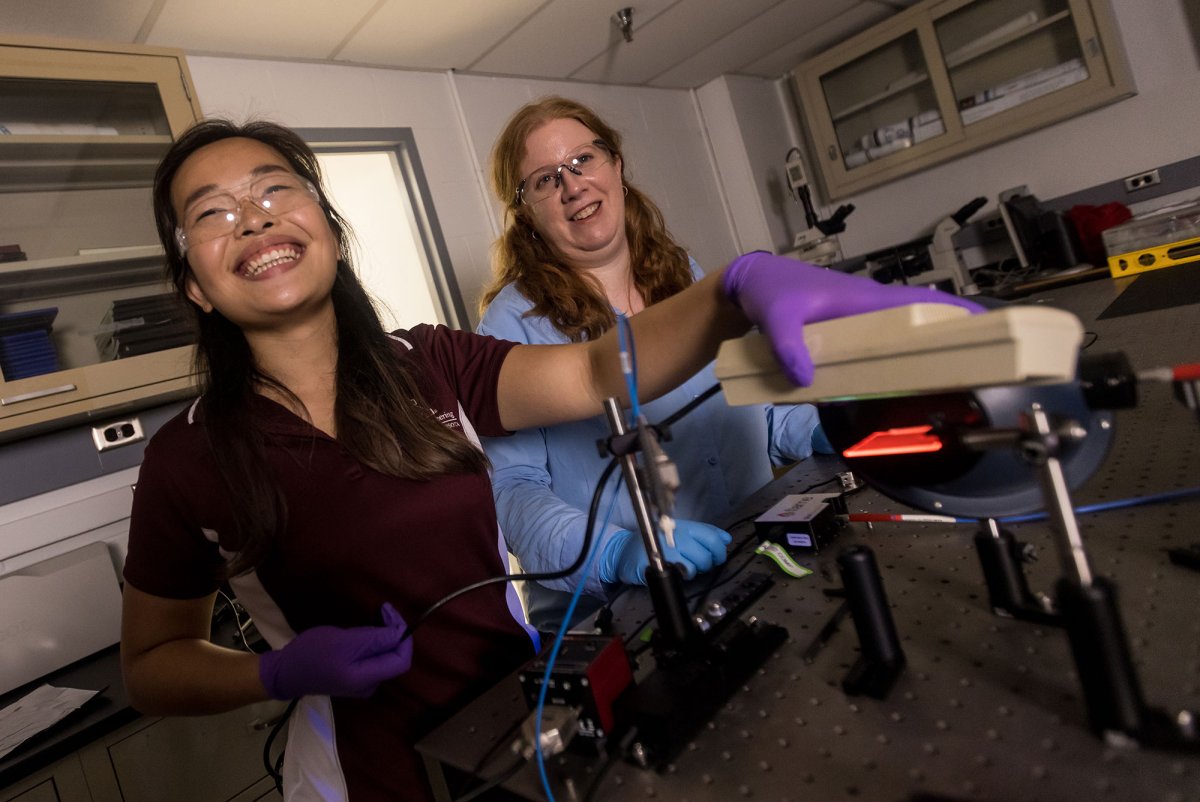

Although still in development, this is the sort of technology that chemical engineering and materials science Associate Professor Vivian Ferry’s research makes possible. Her lab specializes in solar energy and optical materials, or substances scientists can leverage to harness the power of light.

“We create materials that interact with light—manipulate it, guide it, change reflection, change absorption, etc.,” Ferry explained. “Our goal is to modify all these optical properties and then integrate them into a number of different advanced application spaces, like photovoltaics, clean energy development, and finding ways to increase the efficiency of our solar panels through optical design.”

A big part of Ferry’s research is hands-on—physically fabricating materials and devices in the lab and adding tiny patterns on their surfaces in order to alter their properties for the better. The other half of her research is computational.

Ferry and her students use computer modeling and real-world weather data to test how well their innovations would work, say, integrated into solar panels in an agricultural field. Her group is working with mechanical engineering Professor Uwe Kortshagen to plan how they can install their technology in greenhouses and farms to create more seamless energy-saving, sun-powered systems.

It’s that collaborative spirit present in both the College and the Department of Chemical Engineering and Materials Science that initially drew Ferry to the University of Minnesota. That, coupled with the one-of-a-kind facilities and resources on the Twin Cities campus like the Characterization Facility and the Minnesota Nano Center, both of which Ferry and her researchers frequently use.

“I think the fact that we are chemical engineering alongside materials science is really beneficial because you get that perspective from lots of disciplines to tackle problems that are inherently interdisciplinary,” Ferry said. “Materials span lots of other disciplines in lots of ways. I love that being a ‘college of science and engineering’ is useful for being able to make those kinds of connections.”

Research to industry: Rewriting the chemistry playbook

In the process of biomass pyrolysis, thousands of chemical reactions happen in the span of a few seconds. Bio-based ingredients like plants, grass, and corn are heated to extremely high temperatures until they melt into a substance that resembles crude oil.

It’s an exercise in chemical experimentation that scientists never truly understood—until 2014 when UMN chemical engineering Professor Paul Dauenhauer and his then Ph.D. student, Christoph Krumm, found a way to study it. They developed a reactor system that essentially allowed them to spread chemical reactions out over long periods of time so that they could analyze what was really happening.

That innovation eventually allowed the researchers to discover new ways to create useful biofuels and chemicals from plants. In 2016, they commercialized their findings and formed Sironix Renewables, a startup with a mission to replace petroleum-based materials in cleaning products with eco-friendly, plant-derived ingredients that actually work better than their fossil fuel counterparts.

“Green and bio-renewable products are becoming increasingly important, and companies are making strong commitments to it,” said Krumm, who’s now the CEO of Sironix, based in Seattle, Wash. “But it’s still a big barrier for businesses to switch from petroleum. Over the next five years, we plan to rapidly scale the process where we can produce large quantities of the product and actually sell it to customers.”

Dauenhauer’s lab is well-known for being a treasure trove of sustainable technology. In addition to Sironix, his research has spun into two other startups in the last decade. One of those is Carba, a carbon dioxide removal company that won the 2023 Minnesota Cup Grand Prize of $85,000. The other is Låkril Technologies, which specializes in converting lactic acid from corn into acrylic acid for use in products such as diapers and paint. The startup plans to open a pilot plant by the end of next year.

Låkril leverages a catalysis process drummed up by Dauenhauer’s former chemical engineering Ph.D. student Yutong Pang, who now works as a senior research specialist at Dow Chemical Company in Houston, Texas. Pang said one of the most important things she learned from her former mentor is to approach all projects with a mindset for sustainability.

“Paul’s innovative mindset really triggered us to always think about new ideas,” Pang said. “In his lab we did biomass conversion, plastic recycling, plastic pyrolysis—these are all hot topics in the industry right now, and we got to grow in that academic environment. Since sustainability is also a big component at Dow, being exposed to different ways that you can practice sustainable chemistry was very important for me.”

In 2020, Dauenhauer received the prestigious MacArthur Fellowship, widely referred to as the “genius grant,” honoring his contributions to renewable materials research and the green technology industry.

“Paul is someone who approaches a problem barely within the constraints of what our physical world is capable of,” Krumm said. “He’ll push research to the very edge of the laws of thermodynamics and come up with really unique ideas. Not all of them work, but the one thing that does has a massive impact. That’s something I’ve really taken to heart. There aren’t enough crazy ideas being tried. If no one’s tried it, then why not?”

The Center for Sustainable Polymers

The University’s NSF-funded Center for Sustainable Polymers (CSP), directed by Professor Marc Hillmyer, plays a critical role in generating environmentally friendly solutions for the plastic industry and fostering collaboration both within and outside of UMN.

What is a Polymer?

Polymers are chemical compounds made up of long chain molecules containing repeated units. They are found in everything from proteins in our body to the plastics and rubber materials we use every day.

Since its inception in 2009, CSP has grown to be one of the most prolific research centers in the sustainable polymers realm:

Foam it up

CSP origin startup Valerian Materials, which makes sugar-derived monomers and polymers for sustainable products, received a $1.1 million BioMADE grant last year to fund further development. Another company, BKB Floral Foam, Inc.—co-founded by CSE Ph.D. student David Goldfeld—took first place at the 2022 Minnesota Cup and expects to reach $50 million in annual revenue by 2027.

Looking to the future

The Midwest Sustainable Plastics Innovation Regional Engine (M-SPIRE), a U of M-led effort to drive the global transition to sustainable plastics, was chosen as one of 16 finalist in NSF’s Regional Innovation Engines competition with the potential for $160 million in NSF funding over 10 years.