Sustainable Transportation

Optimizing the big machines

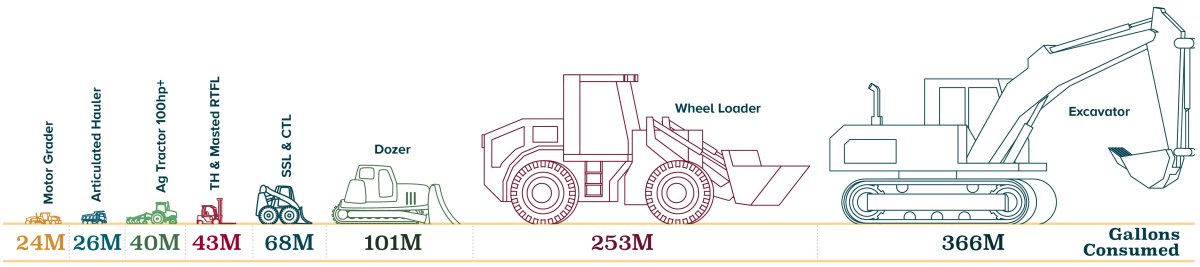

While more cars are running on biofuels and electricity, their off-road cousins—specifically in agriculture, construction, forestry, and mining—have not changed much. Most of them still run on fossil fuels.

Off-road vehicles represent 10 percent of transportation CO2 emissions in the United States, and this number will keep climbing if attention remains with on-road vehicles.

“There are many universities in the U.S. that work on passenger cars and new technology for them, but there are very few who work on medium and heavy equipment or off-road vehicles. That is what we’re focused on,” said Kim Stelson, founding director of the Center for Compact and Efficient Fluid Power at the University of Minnesota.

One reason that off-road vehicles are difficult to decarbonize is their demanding energy and power requirements.

“Carbon-based fuels like gasoline or diesel have 40 times more energy per unit mass than batteries—and that factor of 40 is what has made them necessary in these machines,” he explained. “All a car has to do is move itself along a road. But something like an excavator also has to dig soil and dump it. So its power levels as you dig goes up and down, and the engine has to go fast or slow, while fully loaded or lightly loaded. All of this variation reduces the efficiency of the engine and it increases the emissions.”

Stelson is part of a multidisciplinary team looking to achieve net-zero carbon emissions for off-road vehicles by 2050. Since 2019, the U.S. Department of Energy has invested more than $8 million into studies at CSE on this topic.

“We believe it’s possible to cut their greenhouse gas footprint in half with things that are not exotic, using technology that could be developed and commercialized within years,” he said.

“To potentially save 1.2 quads (351 billion kilowatt-hours) of energy,” Stelson added, “we must operate the engine efficiently, eliminate the throttling valves, store and release energy better, and install smarter controls to manage everything.”

Simply put, Stelson and the other main investigators—Perry Li, Will Northrop, Zongxuan Sun, and Jim Van de Ven—are building a better system.

Close industry partnerships have been vital in progressing the team’s research. CNH Industrial has been a key partner in recent projects. In addition to providing an engine for experiments aimed at learning how to operate a wheel loader most efficiently, the company gave a compact track loader to a study on optimally pairing hydraulic and electric power

transmission.

“The University of Minnesota is well-positioned to lead in this area because we have significant research expertise in fuels, energy conversion, actuation, sensing, and control for target applications,” said Stelson.

So, what’s the best net-zero solution for off-road vehicles? Is it going to be green hydrogen, green ammonia, or biofuels? Will we combust it or use fuel cells? Will some of these vehicles be fully electric, or will they combine electricity with other power sources?

“The answer probably is yes to all of those options,” said Stelson. “There’s not a simple answer. What’s right for working in a mine might be different from what’s right for working in a corn field.”

Assistant Professor Michael Levin is studying signal timing models for better traffic flow and less pollution from idling cars

The National Cooperative Highway Research Program is funding Professor Mihai Marasteanu’s studies on asphalt binders and mixtures

Leading electrification

Partnerships result in nation's first grad certificate program in electrification

The University of Minnesota’s Technological Leadership Institute (TLI), in collaboration with the Minnesota Department of Employment and Economic Development (DEED), Toro, Polaris, and Design Ready Controls, recently launched the Minnesota Center for Electrification Opportunity (MN CEO).

This pioneering consortium will lead workforce development training and industrial upskilling through a partnership between the University of Minnesota and nationwide industry leaders in electrification.

“The conversion of fossil fuel technologies to electric and hybrid power systems promises to be a decades-long process requiring enormous talent and organization,” said Allison Hubel, director of

TLI and mechanical engineering professor in the College of Science and Engineering.

In December 2022, TLI partnered with Thermo King, a leader in transport temperature control solutions, to launch the nation’s first-ever graduate credential in electrification engineering.

The in-person and online program covers the breadth of technologies used to convert traditional mechanical systems into hybrid or electric platforms. It is designed for industry professionals and new college graduates—and driven by industry demand for a robust talent pipeline in fields including renewable energy policy.

The Electroposium, a recent event showcasing the University’s electrification expertise, drew about 350 leaders in industry, government, and academia, including Minnesota Gov. Tim Walz.

“To use a very Minnesota metaphor, we don’t want to end up chasing the puck,” Walz said.

“Through these programs, we’re finding ways to bring more Minnesotans into the labor market, grow our economy, and help businesses and workers thrive.”

To view more photos from Electroposium 2023, see the College of Science and Engineering album.

Alumnus builds a better e-bike

Lectric is one of the fastest-growing companies in the U.S.

Robby Deziel’s story is an inspiration to any engineer with an entrepreneurial spirit. As co-founder and chief innovation officer for Lectric eBikes, he gets to combine his knack for mechanical engineering, leadership, and design with his passion for clean energy.

Fresh out of college in 2018, with mechanical engineering degree in hand, Deziel co-founded the company with his longtime friend, Levi Conlow. At the time, the national market for electric bikes was relatively limited and expensive.

With inspiration and funding from Conlow’s dad, the two started their business with an ambitious mission: “to provide the most accessible and adventurous e-bikes ever.”

They had a rough ride with their first model, which simply wasn’t selling. To find out why, they gathered extensive feedback from their target customers. The consensus was that the bike looked uncomfortable and it was too hard to get on and off.

“We basically went back to the drawing board,” said Deziel.

They changed everything from the frame and wheel size to the seat, handlebars, and tires. They also made the bike foldable so riders could easily transport and store it.

Enter the Lectric XP. The totally new e-bike model earned them $1 million in three weeks.

Lectric went from selling just a couple bikes per month in 2019, to $2 million worth of XPs per month by 2020. Today, Lectric is one of the fastest-growing companies in the

United States, with 120 employees and 350,000 bikes in circulation.

Deziel’s UMN experience gave him the confidence to lead his team at Lectric. He credits the mechanical engineering senior design capstone in particular. During this course, Deziel led five students in a 3M-sponsored competition to develop an impact-resistant airdrop container for emergency medical supplies.

“We had these talented people with their own strengths and abilities, and I was learning how to get the most out of them as a leader,” he said.

“We had roadblocks, personality conflicts, design issues. We had to develop testing procedures and protocols, and get buy-in from stakeholders,” Deziel recalled. “That capstone experience was super beneficial to me and the closest thing to how it actually is out there in the real world.”

STORY BY EVE DANIELS