ME Partners with Medtronic to Develop 3D-Printed Aortic Valve

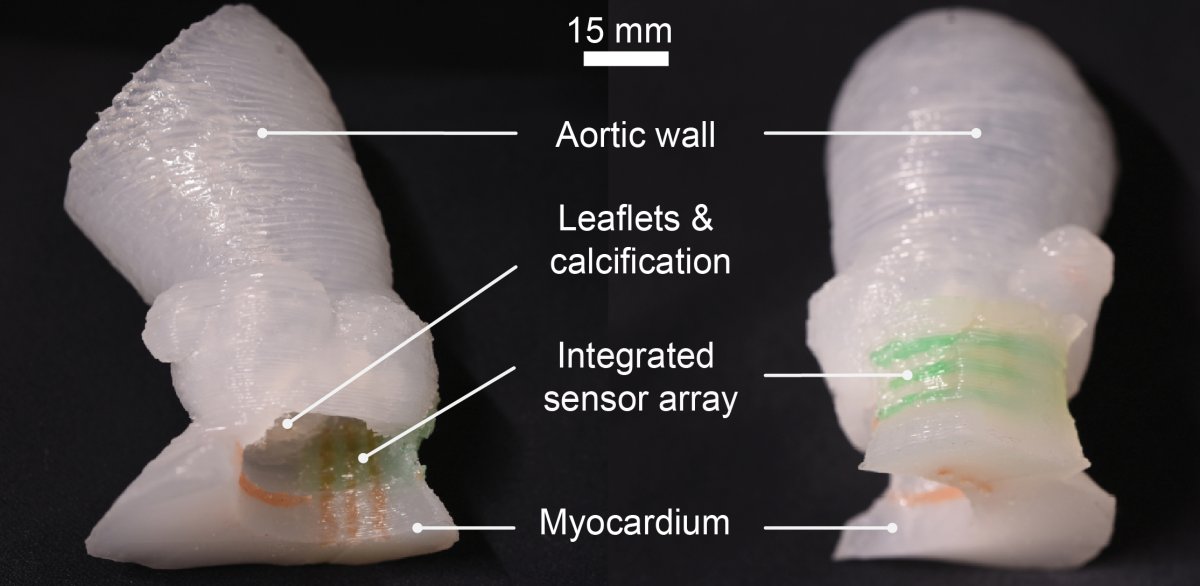

Professor Michael McAlpine's team, with support from Medtronic, developed a groundbreaking process to 3D print multi-material lifelike models of aortic roots. The result is a structure that mimics the exact look and feel of a real human heart valve.

Researchers used specialized inks and a customized 3D printing process to create the aortic root, which consists of the aortic valve and openings for the coronary arteries. These models can be used by surgeons to prepare for minimally invasive procedures, which could improve outcomes for thousands of patients worldwide. This particular model was designed to help doctors prepare for a Transcatheter Aortic Valve Replacement, a common treatment for aortic stenosis, which affects about 2.7 million adults over age 75 in North America.

“Our goal with these 3D-printed models is to reduce medical risks and complications by providing patient-specific tools to help doctors understand the exact anatomical structure and mechanical properties of the specific patient’s heart,” said Michael McAlpine, a University of Minnesota mechanical engineering professor and senior researcher on the study. “Physicians can test and try the valve implants before the actual procedure. The models can also help patients better understand their own anatomy and the procedure itself.”

The McAlpine group's research was published in Science Advances and funded by Medtronic.

See the printing process in action and take a look at the final product: