Students to the Rescue!

Motorola had a problem. Graduate students at an IMA workshop found a solution that saves the company $300K per year. And they enjoyed an unforgettable lesson in the power of mathematics.

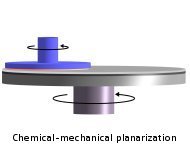

The pads used to polish silicon wafers in their chemical-mechanical planarization systems were wearing down too quickly and the impact on production was very costly. At the 1998 Industrial Mathematics Modeling workshop, Motorola scientist Len Borucki asked six graduate students in his assigned team to try to get a handle on pad wear through mathematical modeling. During the ten-day workshop, the students worked together to develop a simple mathematical model which incorporates the relevant physical processes, and created a prototype computer implementation. Impressed with the results, Borucki had the model refined at Motorola where it is now deployed companywide to minimize pad changes.