Researcher Highlights

CharFac will be featuring research highlights in our newly revamped newsletter (first issue Fall 2023). The research highlights will be archived below.

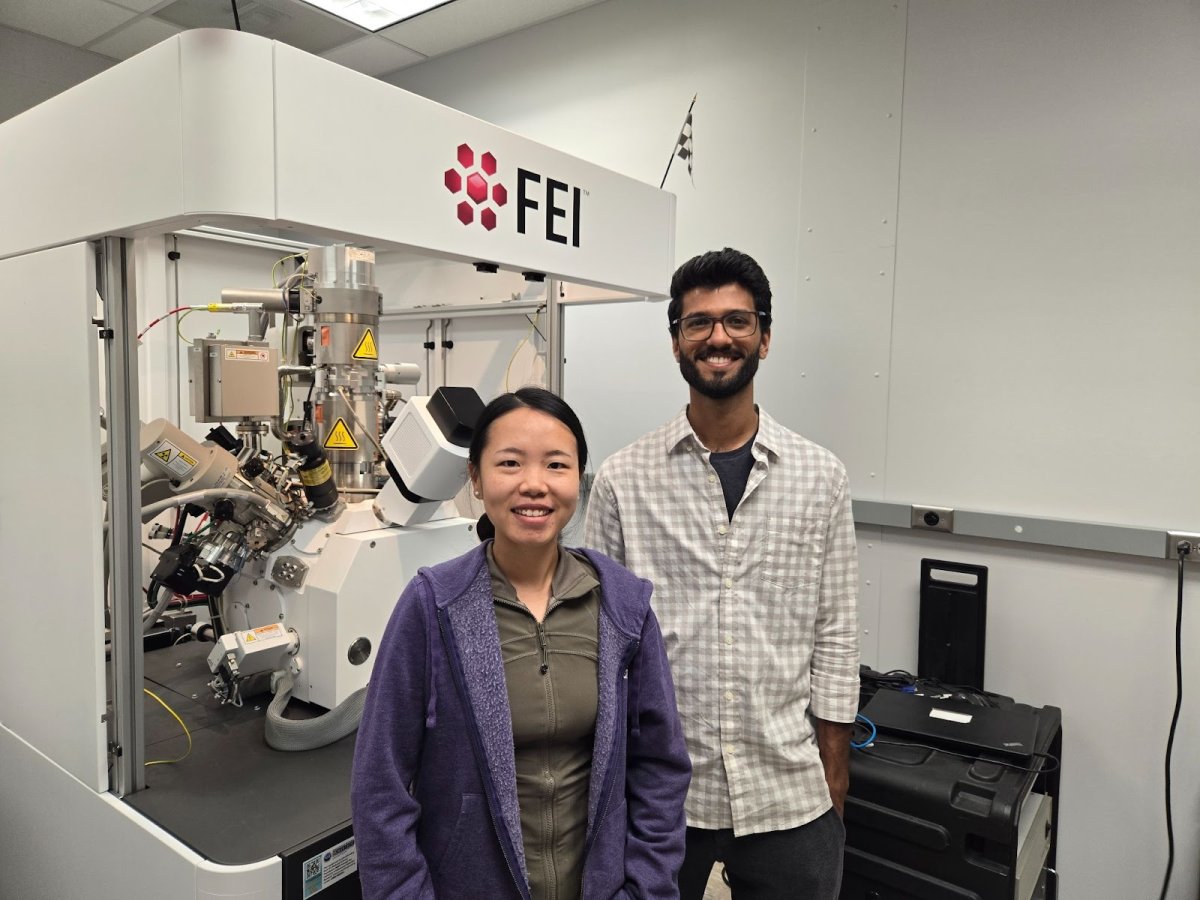

Silu Guo and Sreejith Nair - Summer 2024

The Summer 2024 issue of our newsletter features work from Silu Guo and Sreejith Nair, both from the Department of Chemical Engineering and Materials Science. Silu Guo, a rising 6th year PhD candidate working with Prof. Andre Mkhoyan has made significant contributions to the atomic-level study of nanomaterials using the FEI aberration corrected Scanning Transmission Electron Microscopy (STEM) in the Characterization Facility. Among the vast array of materials that Silu has studied over the past few years, her recent work on radiolysis-driven healing of nanoscale cracks in rutile TiO2 has attracted lot of interest from the materials science community due to its immense potential in developing methods for controlled healing of defects in materials and furthering the understanding of atomistic processes that occur during energy excitation. A combination of high-resolution STEM, electron energy loss spectroscopy, theoretical modeling and simulation, led Silu to precisely elucidate the atomistic restructuring process and identify the driving forces and mechanisms for the crack healing.

Closely related is work from Sreejith Nair, a rising 5th year PhD candidate working with Prof. Bharat Jalan. Sreejith’s work involves synthesizing atomically precise metal oxide thin films using Molecular Beam Epitaxy (MBE), which is a state-of-the-art ultrahigh vacuum technique for thin film growth. Sreejith uses metal-organic precursors to supply different metals for thin film growth, a technique pioneered by the Jalan Lab, which resolves challenges associated with the sublimation and oxidation of pure metals that are conventionally used in MBE. Sreejith’s work on epitaxially strained IrO2 thin films grown on TiO2 substrates, led to the first demonstration of engineering metal oxidation using epitaxial strain provided by the substrate and also led to the observation of high mobility charge carriers in IrO2 thin films. The work heavily relied on thin film structure and composition analysis using the high resolution X-ray diffractometer, Atomic Force Microscope, Scanning Electron Microscope and X-ray Photoelectron Spectroscope, all housed in the Characterization Facility in Shepherd Labs.

Silu and Sreejith’s work is also a testament to the collaborative nature of research. Sreejith’s work on IrO2 thin films had significant contribution from the atomic level visualization of metal islands on the oxide thin films enabled by the spatially precise TEM sample preparation by Silu using the Focused Ion Beam facility and the subsequent high-resolution STEM and EELS measurements. At the same time, Silu’s work on nanoscale cracks in TiO2 was the result of a meticulous eye for detail from Silu on the IrO2 samples grown by Sreejith, which due to epitaxial strain had formed cracks in the TiO2 substrate. With the advanced state-of-the-art equipment at the Characterization Facility, their collaboration advances material synthesis techniques and enhances understanding of microscale dynamics, providing insights for next generation electronic devices design.

Tzia Ming Onn - Fall 2023

My research motivation is to address sustainability-related issues. Our current approach in CEMS combines technologies used in electronics with heterogeneous catalysis to describe a platform known as the graphene catalytic condenser or catalytic capacitor.

This solid-state model system relies on the condensation of charge in the catalyst. Because electrons participate directly in chemical transformation, charges condensed in the catalytic sites affect activity as evident in our recent work involving amorphous semiconductor alumina and platinum nanoclusters. This has led to the establishment of the Center for Programmable Energy Catalysis or CPEC, a DOE funded EFRC center at UMN, and the Characterization facility (CharFac) has been and will continue to be a major pillar of support for our work.

Our recent work has undergone comprehensive characterization owing to the ease of access and training provided by CharFac to high quality equipment such as microscopes (TEM, SEM, STM, Confocal Raman, etc.), spectrometers (XPS, UPS, etc.), diffractometer (XRD), and more. I cannot overstate how important the CharFac experts have been with regards to tackling specific problems related to characterizing our catalytic condenser materials (which is not trivial), processing and handling samples, and setting up customized parts for better characterization in the future. With electron/photon-driven catalytic approaches becoming more recognized as a disruptive force in reducing our society’s dependence on fossil resources, the in-situ characterization of charged materials will become more and more necessary. I am fortunate that CharFac has the facilities and expertise to enable more high-quality work in the near future for UMN.