New uncooled infrared detector with high sensitivity to significantly expand thermal imaging field of applications

Scientists have built an uncooled infrared thermal detector that is significantly more sensitive than existing state-of-the-art detectors. The development has the potential for a wide range of applications from biosensors to manufacturing and refinery units to automated driving systems.

Researchers led by Professor Joseph Talghader have fabricated an uncooled long-wave infrared (IR) thermal detector that has demonstrated superior performance at room temperature across several key detector metrics. Essentially, the team has developed the world’s most sensitive IR detector that does not require any cooling. IR detectors or cameras have commercial, industrial, and military applications, and this development has the potential to further expand their use and application.

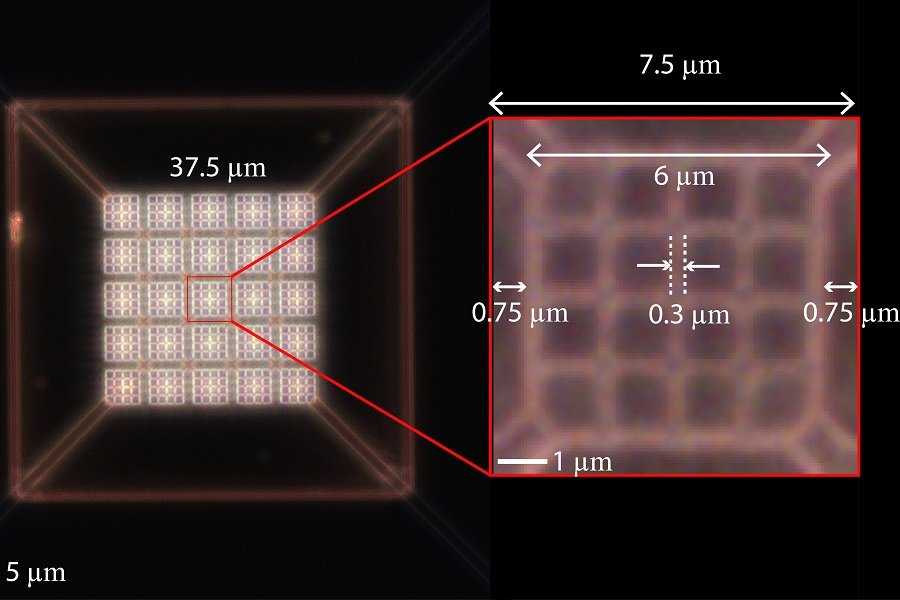

Details of the work are published in Optica in a paper titled, “Thermodynamically limited uncooled IR detector using an ultra-low mass perforated subwavelength absorber.”

Avijit Das, a key contributor to the paper talks about the significance of the team’s work: “We have developed an uncooled detector for IR cameras with very high sensitivity, whose applications range from the biomedical industry to construction to even sports. Such a detector can be used to develop biosensors, and detect stress points in buildings, bridges, or other structures. It can be used to even review contested calls by umpires in sports. The range of applications is vast.”

All objects including ice cubes emit thermal radiation (wavelengths in the range of 8 to 14 microns, far outside our visible range) known as their heat signature. The hotter the objects are, the more infrared radiation they emit. What a thermal detector essentially does is absorb this infrared radiation, which causes changes in its temperature. This change is then indicated through an electrical or optical signal by the detector. Sometimes the detector’s temperature noise (changes in the temperature within the device even when nothing is happening) can get too high, drowning out the temperature change of what you actually do want to see happening in the object.

There are two classes of thermal cameras: those with cooled (with a cryogenic cooler) detectors and those with uncooled detectors. IR cameras with cooled detectors have lower thermally induced noise and are therefore highly sensitive to signals from the object or scene that a user is trying to view. However a cooled detector also comes with considerable disadvantages: they are larger, heavier, and significantly more expensive.

On the other hand, IR cameras with uncooled thermal detectors are affordable and portable (some of them can even be hooked up to your smartphone to view images), which makes them more accessible for use. Night time wildlife footage and security camera images are familiar examples of their use. However they are thermally noisier.

Talghader and his team of researchers have developed a detector that belongs to this uncooled class of thermal IR cameras. The ultimate performance in such a camera would be one where the device is sensitive enough for it to register temperature fluctuations, but not enough for the fluctuations to compete with the signal of the object or scene you want to see. The quest for that sweet spot has brought the sensitivity of uncooled detectors in IR cameras currently available to approximately 20 to 40 milliKelvins (mK). However, in a significant leap forward, the detector built by Talgahder’s team has a sensitivity of 4.5 mK, the smallest temperature change (also known as, noise equivalent temperature difference) that the detector can sense. The sensing capability of the detector (in technical terms, detectivity) is the key highlight of their work, and it has the potential to considerably expand the field of applications for IR cameras with uncooled detectors.

The researchers have tested their detector against results recorded in over 70 published works on state of the art uncooled IR detectors. The new detector’s key performance metrics were compared to those of existing uncooled cameras using theoretical calculations and experimental measurements. Having theoretical as well as experimental verification is particularly critical as it demonstrates the detector’s readiness for manufacture and use.

“We have made the world’s most sensitive IR detector that does not require any cooling. Uncooled detectors are more affordable than cooled detectors, and with the new increased sensitivity we will look at a broad range of applications. These detectors are capable of a lot more than providing security images,” says Talghader, speaking about the significance of their work. “Anytime you want to look at something at night or in low light conditions, this is the technology you want to use. They can be used to detect leaks and hot spots that are particularly useful in industrial settings such as manufacturing units and refineries. Thermal IR vision can also ensure safety in automated driving systems.”

The details of the team's work are in the paper, "Thermodynamically limited uncooled IR detector using an ultra-low mass perforated subwavelength absorber.”

The research was funded by the Army Research Office and the Minnesota Nano Center (a part of the National Nanotechnology Coordinated Infrastructure network (NNCI), a group of nanotechnology labs located around the country and supported by the National Science Foundation (NSF).

The research team comprised Avijit Das (Ph.D. candidate and lead author), Merlin Mah (postodoctoral research associate), John Hunt (Ph.D. candidate), and Professor Joseph Talghader (corresponding author), all from the Department of Electrical and Computer Engineering.