Renovation Complete, SAFL Looks Ahead

As a unique research facility built directly into the banks of the Mississippi River, the St. Anthony Falls Laboratory (SAFL) is a piece of Twin Cities history. It was also, in 2009, falling apart. The Upper Deck, which allows vehicle access to the building, was structurally unsound and in danger of caving in on the heads of researchers working below in the Sediment Lab. The 1950s-era elevator no longer worked, and the lack of air conditioning or any form of climate control meant that the sensitive equipment in the SAFL atmospheric boundary layer wind tunnel was out of commission for the humid months of summer.

In 2009 the National Science Foundation, bolstered with additional funds through the American Recovery and Reinvestment Act, issued a call for proposals to their Academic Research Infrastructure Program: Recovery and Reinvestment, which supports restoration of critically important research facilities. SAFL’s proposal focused on supporting its work in biofuels, wind and marine and hydrokinetic energy, and restoration and protection of streams, rivers, and deltas. The proposal earned an unprecedented six “excellents” in the peer review process and garnered SAFL $7.1M. Unfortunately for the infrastructure, NSF funds could only be applied to research-related renovations. The University of Minnesota stepped in with over $9M through the Higher Education Asset Preservation and Replacement (HEAPR) funds to reinforce deteriorating concrete and bring the building up to current codes.

HEAPR funds allowed SAFL to add a sprinkler system and a new elevator and stair tower, install new plumbing, building-wide electrical service, and install Director Fotis Sotiropoulos’ favorite new feature: a climate control system.

“It seems trivial,” he says, “but it isn’t, because it gives our staff the ability to function day-to-day. It still needs tweaks, but we now have reasonably functional climate control. Before the renovation, we had window units and radiators in the offices, but we had nothing on the research floors. It was not comfortable to work in, and it interfered with precise science.”

Research renovations expanded the labs and flume areas, but they also included rebuilding safety measures in some of SAFL’s most iconic facilities. The Main Channel, 275 feet long and fed directly by a roaring supply of Mississippi River water, was outfitted with new baffles, safety gates, and emergency shut-off system, as well as a new wave generator. These features mean that SAFL researchers can explore their Department of Energy-funded work in offshore wind energy and marine and hydrokinetic energy.

“The wave generator was not operative, it was last used 50 years ago and was not compatible with the upgraded electrical system” explains Dr. Michele Guala, an assistant professor who joined SAFL just before the renovations. His team is working on a long-standing challenge in studying offshore wind turbines installed on floating platforms. Working with the new wave generator in the Main Channel and in the newly updated wind tunnel, they can decouple wave effects from wind effects and investigate offshore wind power plant performance through two opportunely scaled experiments.

Answering this question also relies on sophisticated thermal control of the wind tunnel. “We had thermal control before the renovation, but it was dodgy and partly manually controlled. Now, it’s all automated; it can be operated by a student in a safe and reliable way,” says Dr. Guala. “Now that we’re through the process, I am really excited to work with such a great set of facilities.”

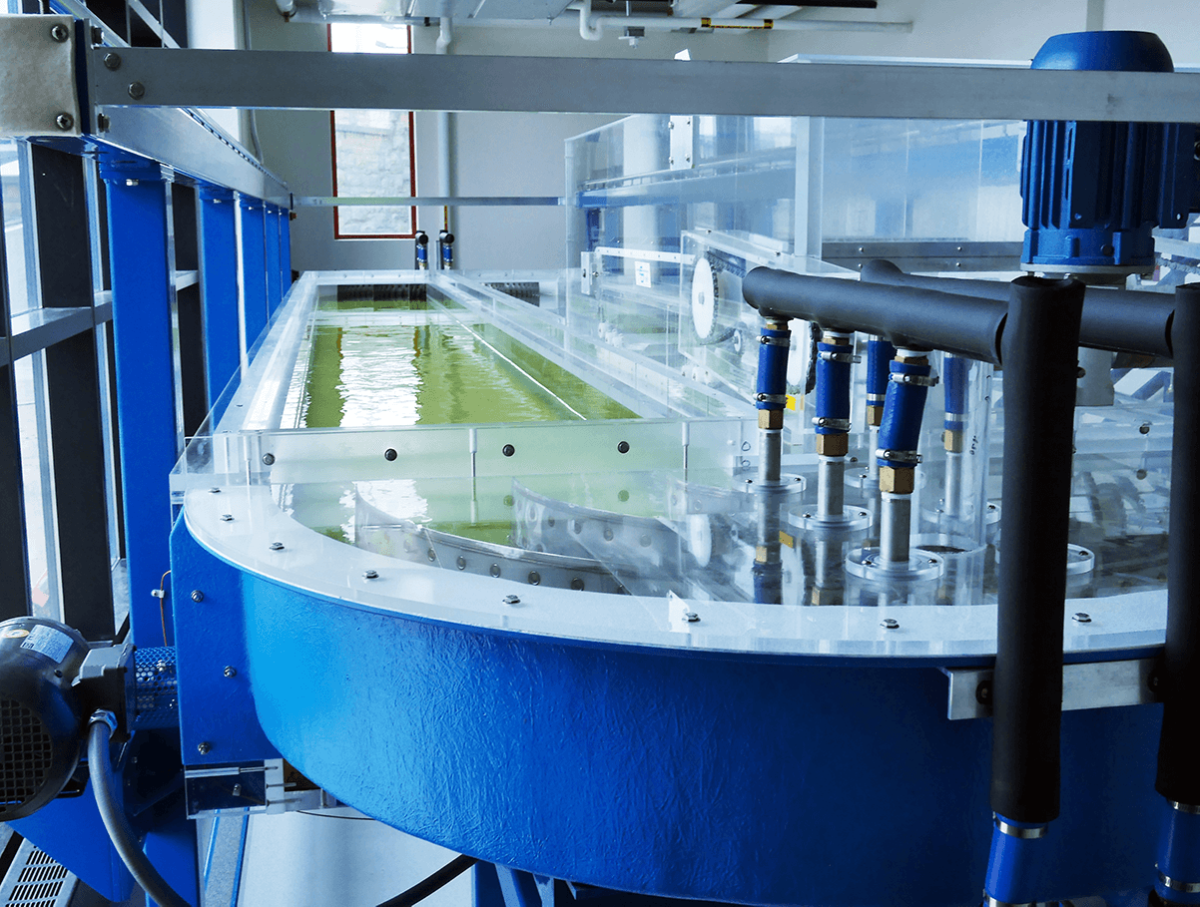

Guala isn’t the only researcher whose work has benefited from expanded facilities. Drs. Miki Hondzo and Jessica Kozarek are studying the effects of turbulence on controlling invasive zebra mussel for the U.S. Army Corps of Engineers, and their work is centered in the newly outfitted EcoLab.

“SAFL started as a traditional hydraulics lab, focused on engineering problems, hydropower, water supply, and sediment transport,” explains Dr. Hondzo, who is also SAFL’s Associate Director of Research and Development. As the research focus of the lab broadened to include geosciences and ecology and studied the biological and chemical interactions with fluid mechanics “we didn’t have the facility for this. Such research cannot be done on the Model Floor, which is dusty and dirty. It requires a controlled environment for temperature, light exposure, nutrient concentration, and minimal microbiological contamination. These factors need systematic organization, and we put that in with the renovation.”

The updated EcoLab is also hosting a project with the Minnesota Department of Agriculture that addresses denitrifying bacteria in streams as a way of reducing nitrate pollution in drinking water resources, an NSF project aimed at controlling blue-green, or mycrocystis, algae that releases toxins into fresh water bodies, and a green algae project studying its uses in biofuels and human nutrition.

While the researchers and students of SAFL have gained a great deal, the renovations have also opened the lab up to new educational and outreach opportunities. The broken elevator and narrow stairways once meant that anyone with special needs could not safely visit the Lab but now “that’s all fixed,” says SAFL’s Associate Director of Engineering and Facilities Jeff Marr. “We can accommodate anyone now, and that’s really important for building collaboration with our science colleagues and the public.”

And the accessibility of the Lab may become even more important if Dr. Sotiropoulos gets his way. “The lab is growing. Our promise to NSF was to make this a national research facility focusing on the nexus of energy and the environment. We have more faculty in the College of Science and Engineering collaborating with us, and we have high profile education and outreach events. Researchers from around the world want to come and work here. This creates a demand for space. So, we’re starting to try to come up with new, creative ways to expand space. This is all pie in the sky right now, but that’s how we started with the renovation.”