Coring and Drilling Systems

The CSD Facility maintains an array of specialized field equipment to support scientific coring and drilling. Facility equipment includes water samplers, soft sediment coring systems for most environmental settings, and lightweight drills for shallow rock coring. Complementing these and other sampling systems are a suite of vessels and platforms designed for use in a range of open-water settings. Many of the systems described below are available for purchase from the Facility, or rental from the Facility equipment pool. To rent field equipment from the CSD Facility please fill out our Equipment Rental Form and contact Ryan O'Grady (612-301-8288, ogra0014@umn.edu) for information about equipment and scheduling.

The CSD Facility contracts drilling companies to provide deep drilling and coring services beyond Facility equipment capabilities. Staff can provide more information regarding all coring and drilling equipment and techniques, whether owned and operated by the Facility, community scientists, or commercial contractors. Contact Facility staff to discuss the best approaches and costs for your project.

Lake Sediment: Surface Corers

These devices are used for recovering the sediment-water interface in lakes and shallow water environments, and sediments immediately below the surface. They are all single-drive corers—they cannot be used to take a second, deeper core at a location already sampled.

+

Ekman Dredge

Ekman dredges (Ekman, 1911) are essentially metal cubes with side length ~15cm, and a pair of spring-gate doors that are held open during deployment and closed during recovery. The box is lowered into the sediment via rope. The operator slides a messenger down the rope, which closes the doors, and the sample is returned to the surface. Recovered sediments are assumed to be mixed.

- Type: Grab

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): limited by wire/rope length

- Maximum Sediment Depth (m): 0.2

- Dimensions and Weight: 2 kg, 20x20x30cm

- Minimum Open-Water Deployment Requirement: canoe/kayak

- Core Diameter/Profile (cm): 20 x 20 x 30, box

- Lithologies: Soft Sediment

- Contact: CSD Facility

+

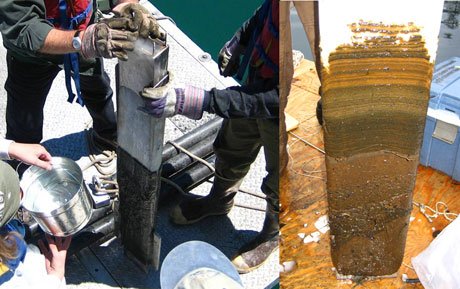

Freeze Corer

Freeze corers consist of a steel wedge 1.5m tall, ~15cm wide, and ~8cm deep at the top. The wedge is filled with a mixture of dry ice and alcohol, and lowered into the sediment via rope or standard Livingstone drive rods. The corer remains in this position for ~10 minutes while sediment freezes to the outside of the wedge, then returned to the surface. The dry-ice alcohol slurry is poured into a bucket, and the frozen slabs of sediment on the outside of the corer are removed and preserved in a cooler with dry ice. Freeze corers produce exceptional samples of near-surface sediments, which can be difficult to recover without disturbing the fragile sedimentary structures. Corer length determines the maximum depth of recovery.

- Type: Freeze

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): limited by wire/rope length

- Maximum Sediment Depth (m): 1.5

- Dimensions and Weight: 13 kg, 150x20x10cm, plus dry ice and alcohol

- Minimum Open-Water Deployment Requirement: canoe/kayak

- Core Diameter/Profile (cm): 150 x 20 x 2, slab

- Lithologies: Soft Sediment

- Contact: CSD Facility

+

Gravity Corer

HTH Gravity Corer

The HTH Gravity Corer is a rope deployed self-triggering valve-top corer that penetrates the sediment under its own weight. The standard configuration collects cores in polycarbonate tubes 70mm diameter x 0.5m length. The corer, however, can be outfitted with tubes up to 1m in length for suitable lithologies. Recovered cores can be secured and capped in the tube for transport or they can be extruded at 5mm (or coarser) depth resolution on site.

- Type: Gravity

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): limited by wire/rope length

- Maximum Sediment Depth (m): 0.5

- Dimensions and Weight: 7 kg, 20x20x30cm, plus core tube

- Minimum Open-Water Deployment Requirement: canoe/kayak

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Accessories: Core liners, Core liner caps, Slicer extruder

- Contact: CSD Facility

MUCK Gravity Corer

The MUCK gravity corer is deployed on a rope, and lowered into the sediment under its own weight to recover an undisturbed sample of the near-surface sediments. Penetration depth is determined by the amount of weight on the core head, which can range from 5 to 40 kg. A valve in the corer head closes when the deployment rope becomes slack, and provides suction during recovery. Operational constraints for the corer limit its suitability to a narrow set of applications requiring a heavier corer (e.g., the trigger corer for the Kullenberg). In most sediment surface coring applications, other corers such as the HTH or rod-deployed surface corers will be a better choice.

- Type: Direct Push, Gravity

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): limited by wire/rope length

- Maximum Sediment Depth (m): 1.5

- Dimensions and Weight: 2-40 kg, 20x20x30cm, plus core tube

- Minimum Open-Water Deployment Requirement: canoe/kayak

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Contact: CSD Facility

+

Multicorer

Multicorers are lowered on a wire, settle on the sediment surface, and then push three or more short tubes into the sediment simultaneously. These large, heavy frames typically require a powered winch and A-frame or tower and moonpool for deployment.

- Type: Spring-driven, Surface Coring

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): limited by wire/rope length

- Maximum Sediment Depth (m): 1

- Dimensions and Weight: 90-500 kg

- Minimum Open-Water Deployment Requirement: vessel with moonpool or A-frame

- Core Diameter/Profile (cm): multiple cores, each 7-12 cm diameter

- Lithologies: Fine-grained, Soft Sediment

- Accessories: Core liners and core liner caps

+

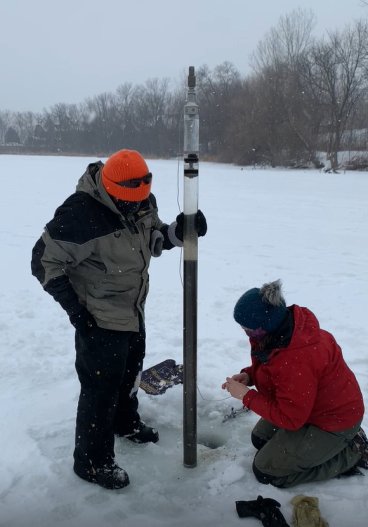

Rod Deployed Piston Corer

Short Square Rod

A corer head is attached to the top of a polycarbonate tube. The corer can then be lowered through the water column to the sediment using drive rods. The core tube is then pushed into the sediment using the drive rods. Like a thumb on top of a straw, the piston inside the tube overcomes the overlying hydrostatic force enabling core recovery. The length of tube and the character of the sediments limit core length, and operation becomes difficult in water deeper than 30m or with core tubes longer than ~3m. Note that this same corer head is compatible with the Livingstone and Bolivia coring systems used for repeat drive coring described below.

- Type: Direct Push, Piston, Surface Coring

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): 30-50

- Maximum Sediment Depth (m): 3

- Dimensions and Weight: 2 kg, 10x10x30cm, plus drive rods and core tube

- Minimum Open-Water Deployment Requirement: canoe/kayak

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Accessories: Core liners, Core liner caps, Zorbitrol/floral foam, Drive rods

- Contact: CSD Facility

Mock Corer

In cases where a corer head is not available, the drive rods can be secured directly to the polycarbonate core tube with duct tape. This technique is low cost and effective, though requires care in securing with tape and some nuance to the corer length used in the depth calculation.

- Type: Direct Push, Piston, Surface Coring

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): 30-50

- Maximum Sediment Depth (m): 2

- Dimensions and Weight: 2 kg, 10x10x30cm, plus drive rods and core tube

- Minimum Open-Water Deployment Requirement: canoe/kayak

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Accessories: Core liners, Core liner caps, Zorbitrol/floral foam, Drive rods

- Contact: CSD Facility

Lake Sediment: Corers for Shallow Lakes

~0 to 30 m water depth

+

Livingstone/Bolivia

The Livingstone-type drive rod piston corer (Livingstone, 1955; Wright, 1967) can be used in water up to about 30m deep to collect successive 1 meter drives down hole of soft to consolidated lake sediment, which are extruded between drives into split tubes and stabilized for transport and storage. Operation is most efficient with a team of 4-5 people, though it is possible with fewer people in certain circumstances.

- Type: Direct Push, Piston, Repeat-drive

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): 30-50

- Maximum Sediment Depth (m): 30

- Dimensions and Weight: 8 kg, 7x7x150cm, plus drive rods

- Minimum Open-Water Deployment Requirement: vessel with moonpool

- Core Diameter/Profile (cm): 5

- Lithologies: Soft Sediment

- Accessories: Casing (soft sediment coring), Core liner caps, core liners, Drive rods, Figure 8, Handle, Livingstone extruder

- Contact: CSD Facility

A modification to the Livingstone, called the Bolivia corer, replaces the Livingstone’s 2" (5 cm) steel barrel with 2.75" (7cm) polycarbonate tube, eliminating the need to extrude cores and providing superior retention of upper watery sediments. When a depth is reached at which sediments are too tough for the polycarbonate tube (usually at least several meters below lake floor, depending on sediment characteristics), it only takes a few minutes to switch to the steel barrel and continue coring in the same hole. The Bolivia can also be deployed with a square rod long enough to take 1.5-meter drives, increasing efficiency. Maximum depths attainable with the steel barrel depend on sediment character but are typically ~15-20m in fine-grained organic sediments. Casing pipe facilitates coring at greater water depths, and is important for re- entering holes for successive drives. Some lithologies may be difficult to collect with the base Livingstone system and may require changes or additions to the system to facilitate penetration or use of a different system altogether. These include: coarse lithologies, stiff/dry clays, desiccation horizons, peat, etc.

- Type: Direct Push, Piston, Repeat-drive

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): 30-50

- Maximum Sediment Depth (m): 17

- Dimensions and Weight: 6 kg, 7x7x150cm, plus drive rods

- Minimum Open-Water Deployment Requirement: vessel with moonpool

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Accessories: Casing (soft sediment coring), Core liner caps, core liners, Drive rods, Figure 8, Pipe cutter, Cutting cylinder

- Contact: CSD Facility

+

Peat Corer

A Livingstone-type drive rod piston corer modified to use a 3- or 4- inch (7.5 or 10 cm) diameter steel barrel with aggressive serrated teeth collects high quality peat cores, even in fresh, woody material. The drive rods are twisted back and forth during coring to cut the fibrous peat with the steel barrel teeth. Drive rods are pinned at the threaded connections to lock during sawing. The corer can be configured in 1.0 or 1.5 m drive lengths. Recovered cores are extruded into split ABS or PVC liners and secured for transport and storage.

- Type: Direct Push, Repeat-drive

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): 30-50

- Maximum Sediment Depth (m): 15

- Dimensions and Weight: 8 kg, 7x7x100cm, plus drive rods

- Minimum Open-Water Deployment Requirement: vessel with moonpool

- Core Diameter/Profile (cm): 5 to 10 cm

- Lithologies: Peat, soft sediment, fine-grained

- Contact: CSD Facility

+

Vibracoring System

To overcome obstacles posed by coarse-grained layers, a concrete vibrator is attached to either a base Livingstone system or clamped directly to a 3" aluminum core tube (depending on depth requirements). The high frequency vibrations are transferred to the core barrel resulting in liquefaction of the annular space immediately adjacent to the core tube, enabling penetration through coarse lithologies. This system is highly customizable and suitable for water depths up to 30m.

- Type: Direct Push, Piston, Single-drive, Vibracoring

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): 30-50

- Maximum Sediment Depth (m): 10

- Dimensions and Weight: 45 kg, 109x45x35cm, plus 3500W generator, tube(s), and drive rods (if using)

- Minimum Open-Water Deployment Requirement: vessel with moonpool

- Core Diameter/Profile (cm): 5-10

- Lithologies: Coarse-grained, Fine-grained

- Contact: CSD Facility

+

Russian Peat Corer

Also sometimes referred to as a ‘flag sampler’, the Russian peat corer design features a blade and chamber that rotate laterally, cutting a half-cylinder sample following insertion into a peat substrate. The device is suitable only for highly organic, decomposed, fine-grained sediment, and is most useful in settings above the water table, where its lateral action may prevent vertical compaction of unsaturated sediment. In any saturated setting or if peat is fresh, coarse, or woody, a larger-diameter, piston-equipped device with a serrated barrel such as the Livingstone peat corer is recommended for collecting unbiased sample.

- Type: Direct Push, Repeat-drive

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): not recommended for open-water settings

- Maximum Sediment Depth (m): 3

- Dimensions and Weight: 7 kg, 100 cm, plus rods

- Minimum Open-Water Deployment Requirement: not recommended for open-water settings

- Core Diameter/Profile (cm): (5 cm half round)

- Lithologies: Peat, soft sediment

- Contact: CSD Facility

Lake Sediment: Corers for Medium to Deep Lakes

~30 - 1,000 m water depth

These devices are used to reach the maximum sediment depth possible, given the particular constraints (water depth, sediment character, tube length) of each device. Unconsolidated materials near the sediment-water interface are typically disturbed, if recovered at all with these corers. With the exception of the Livingstone-type devices, these corers are all single- drive corers: they cannot be used for repeat-drive coring in the same hole. They can reach sediment depths only as long as their core tube. Resistant deposits such as desiccation/soil surfaces, coarse-grained materials (sand, gravel, tephras) thicker than ~10cm, and hardpans formed through precipitation of (e.g.) silica, iron oxides, or calcium carbonate effectively stop downward progress with these corers wherever they occur in the stratigraphy, except as noted.

+

Kullenberg

The Kullenberg corer (Kullenberg, 1947; Kelts et al., 1986) is a single-drive, cable-deployed piston corer that is dropped into the sediment from a short distance (typically 0 to 3m), propelled by the momentum of the heavy (~1000 pounds/450 kg) lead weights on the core head. Cores are recovered in steel barrels lined with plastic tubes (standard polycarbonate for the CSD Facility system). The corer drop is triggered when a gravity corer, suspended on a second cable to the side of the Kullenberg corer, enters the sediment and ceases downward travel—thus most Kullenberg cores have an accompanying gravity core that captures the upper sediments that are disturbed by the long corer. Deployed from a cable, the range of water depths is limited only by the length of cable on the winch. However, the immense weight of the system requires a substantial secondary apparatus to handle the corer. A heavy-duty winch and hydraulic system or power supply must be employed to raise and lower the corer, and if long core barrels are used to increase the depth of recovery, a tower or A-frame must be available for deployment and recovery. The weight and bulk of the system can also create hazardous conditions in any deployment circumstances, but particularly if waves cause the vessel to roll and pitch. Thus, a minimum of two experienced crew plus three additional hands is required for safe operation.

The R/V KRKII is a large platform consisting of two 19-foot (5.5m), 950-pound skiff boats bolted together with aluminum deck plates and beams. It can be disassembled and towed behind a heavy-duty truck or shipped in a standard 20-foot shipping container. It was engineered and custom-built for Kullenberg coring, for which it provides a large, stable work surface, a 6.5m quad-leg tower, and 5m long moonpool. At 6m long and 5.5m wide, it is larger and heavier than is necessary for most other types of coring operations, and it is more difficult to ship and requires more time to assemble than more appropriately-sized platforms

- Type: Gravity, Single-drive, Trigger-release, Wire Deployed

- Minimum Water Depth (m): 2

- Maximum Water Depth (m): limited by wire length (350m)

- Maximum Sediment Depth (m): 12

- Dimensions and Weight: 680 kg plus long steel tubes, without platform

- Minimum Open-Water Deployment Requirement: platform/vessel with 1-ton winch, and tower with moonpool or A-frame

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Contact: CSD Facility

+

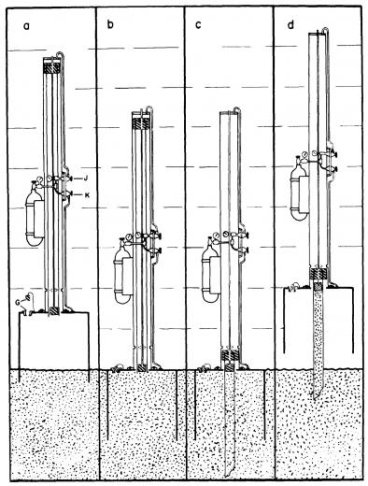

Mackereth Corer

The Mackereth corer (Mackereth, 1958; Smith, 1959) is a pneumatic device that consists of a cylindrical aluminum chamber ~1.2m long and 0.5m in diameter. A pair of 6m core barrel tubes, one of smaller diameter and nested inside the other, is inserted into one end of the chamber and protrudes from its top during deployment. The apparatus is lowered to the lake floor on a rope, and air hoses connect the chamber to the vessel at the water surface. Compressed air is used to pump the water out of the chamber and then to force the inner core barrel downward through the chamber and into the sediment. The chamber then fills with compressed air, which increases its buoyancy and lifts the device out of the sediment and back to the water surface. The system is relatively portable and lightweight compared with other deep-water coring systems, but major inherent operational constraints generally make other coring systems preferable.

- Type: Piston, Pneumatic, Wire Deployed

- Minimum Water Depth (m): 15

- Maximum Water Depth (m): 100

- Maximum Sediment Depth (m): 6

- Dimensions and Weight: 180 kg, 2 pcs. ea. ~50x50x150cm, plus 6m core barrel and tubes

- Minimum Open-Water Deployment Requirement: motorboat

- Core Diameter/Profile (cm): 7

- Lithologies: Fine-grained, Soft Sediment

- Contact: CSD Facility

+

Nesje / Percussion Corer

The Nesje corer (Nesje, 1992) is a single-drive, cable-deployed percussion coring system with a piston, and is operable by two people—although three to four are preferable, particularly as core lengths increase. The core head consists of a steel cylinder to which the core tube is bolted; a rod extending from the top of the head guides a weight (another steel cylinder of ~20kg) as the operator repeatedly lifts the weight a short distance and allows it to drop onto the core head. This system is relatively effective at penetrating clastic and/or coarse-grained sediments. However, plastic core tubes attenuate the percussive strikes, thus limiting its effectiveness at increasing sediment depths. As with all single-drive corers, the length of the tube limits the potential coring depth. Most tubing is available in lengths only up to 6m. If longer lengths are desired, multiple tubes can be coupled together by using a larger diameter plastic coupling over the joint between two lengths of tube. However, such longer tubes pose challenges for handling and for tube stability during the coring process. Like all percussion corers, the Nesje can cause disturbance to the recovered sediment, particularly in sediments of continuously alternating density or grain size (e.g. clastic varves).

- Type: Percussion, Piston, Single-drive, Wire Deployed

- Minimum Water Depth (m): 0

- Maximum Water Depth (m): limited by wire/rope length up to ~100m

- Maximum Sediment Depth (m): 10

- Dimensions and Weight: 23 kg, 20x20x100cm, plus long core tube

- Minimum Open-Water Deployment Requirement: vessel with moonpool or A-frame

- Core Diameter/Profile (cm): 5-8

- Lithologies: Coarse-grained, Fine-grained, Soft Sediment

- Contact: CSD Facility

+

Backpack Drill

Ultra-lightweight conventional diamond coring drills are available through several manufacturers, for shallow drilling (20cm to a few meters) in hard lithologies at remote locations that can be reached only by hiking, helicopter, or other means that require the lightest and smallest equpiment loads. Motors are generally in the range of ~1 kW, fluid circulation is accomplished by a small tank pressurized by a manual pump, and core sizes are small (A or E / 3.3 or 2.3cm diameter). The drill is manually stabilized and the weight of the operator advances the drill string. Like all conventional diamond coring systems, drill rods must be completely extracted from the borehole after each coring run, which limits the rate of coring as depths increase and in fractured or unstable formations.

- Used For: Lightweight, backpack-ready drill system for shallow sampling at remote sites. Best core recovery/quality in hard lithologies.

- Type: Conventional Diamond Coring

- Dimensions and Weight: ~20-50kg, 100x50x50cm

- Core Diameter/Profile (cm): 2.5-5

- Maximum Formation Depth (m): 10

- Lithologies: Rock and other lithified materials

- Contact: Shaw Tool Company

+

Freeze Shoe

The freeze shoe tool is a wireline drilling tool using CO2 cooling techniques to freeze the bottom ~10cm of a coring run in situ, to capture and retrieve soft sediment samples with pore waters intact and uncompromised by mixing or oxidation during recovery, for analysis of microbial communities, minerals, or other constituents that are easily altered during the recovery process.

Modified from the HPC and ALN soft sediment coring tools, the freeze shoe is a P-size tool that collects a 1 meter long, HQ3-size core (61.1mm diameter) in a polycarbonate tube, with the bottom ~15 cm frozen. After drilling the 1 meter run, the tool sits in place briefly while the freezing progresses. The tool is returned to the surface and the core is extracted.

- Used For: Specialized tools to freeze bottom 10 cm of core in situ, prior to recovery, for uncompromised sample for geomicrobiological analyses

- Type: Rotary Diamond Corer (ALN), Wireline Hyrdaulic Piston Corer (HPC)

- Dimensions and Weight: 100s of kg, plus rig, rod, and associated equipment

- Core Diameter/Profile (cm): 6.1

- Lithologies: Coarse-grained, Fine-grained, Hard Sediment, Soft Sediment, Soil/Regolith

- Staff Requirements: professional drillers

- Maximum Formation Depth (m): 200

+

Lake Drilling Tools

Based on the design of IODP soft sediment drilling tools and scaled to allow deployment from small drill rigs, the three Lake Tools collect high-quality soft sediment core samples from modern sedimentary basins and soils.

Each tool requires a P-size drill string (122.6 mm diameter borehole) and collects a 3m long, 66.3 mm diameter core in a polycarbonate liner.

The Hydraulic Piston Corer (HPC) is used in the upper intervals of soft sediment, to depths of ~150 m. It collects core by pumping water into the drill string to create high pressures, which break shear pins in the tool and fires the inner barrel 3m into the sediment. Similar to the IODP Advanced Piston Corer (APC).

The Extended Nose Corer (EXN) is used in firm sediments, after HPC refusal. During the coring run, the drill string is rotated and fluid is flushed through the system to remove cuttings, but the non-rotating shoe of the corer extends ~20 cm below the cutting bit and is pushed into the sediment for an undisturbed sample. Similar to the IODP Extended Core Barrel (XCB).

The Alien Corer (ALN) is a rotary corer, which grinds through hard formations, salt beds, cemented intervals, and other lithologies that cannot be cored with HPC or EXN tools. Similar to industry standard diamond coring tools and the IODP Rotary Core Barrel (RCB).

- Used For: Specialized tools for high-quality cores in soft sediment

- Type: Extended Shoe Corer (EXN), Rotary Diamond Corer (ALN), Wireline Hyrdaulic Piston Corer (HPC)

- Dimensions and Weight: 100s of kg, plus rig, rod, and associated equipment

- Lithologies: Soft Sediment, Soil/Regolith

- Staff Requirements: professional drillers

- Maximum Formation Depth (m): 700 meters, or drill rig limit

- Accessories: Shipping containers

+

Winkie Drill

The Winkie Drill is a portable conventional diamond coring device.

A 2-stroke, 7.5 kW motor with 2-speed transmission rotates the drill rod, a manual press advances the drill string, and a water swivel allows drilling fluid to circulate to the bit and flush cuttings to the surface. As presently configured, A or E size core (3.3 or 2.3cm diameter) can be collected to depths of 60-100 meters. Core quality and maximum depth depend on lithology, with best results in hard, unfractured formations. The drill rod must be entirely removed after each coring run, which slows operations as depths increase and in less-stable formations.

The maximum component weight is 85kg, though the unit can be further disassembled if necessary. Rods, core barrels, bits, pumps, and other items add to the weight of the system, which is stored in a utility trailer for transport to the drilling location. The small size and light weight of Winkie makes it suitable for drilling at remote locations or areas inaccessible to truck or track-mounted rigs, sensitive environments, shallow drilling, concept or test drilling, and training in drilling principles.

- Used For: Portable drill system for sampling at remote sites. Best core recovery/quality in hard lithologies.

- Type: Conventional Diamond Coring

- Dimensions and Weight: 39 kg head, 45 kg press, plus rods, pump, water storage, and associated equipment in utility trailer

- Core Diameter/Profile (cm): 2.5-3.5

- Lithologies: Rock and other lithified materials

- Maximum Formation Depth (m): 100

- Staff Requirements: 1 CSD Facility staff, professional driller, or full training

- Contact: CSD Facility

+

Casing

Casing pipe facilitates direct-push soft sediment coring by limiting drive rod flex in deep water, and provides a temporary conduit to the borehole for re-entry in repeat-drive coring. If needed, casing can be advanced after each coring drive to minimize coring friction and to stabilize the borehole. Images show 4-inch diameter aluminum pipe with circle-lock connectors. Large diameter, thick-wall (Schedule 40) PVC pipe can also be used, with glue-on threaded connectors.

Permanently installed casing for deep drilling projects is provided and installed by drilling contractors according to project specifications.

+

Pipe Cutter and Backing Cylinder

A pipe cutter can be used to cut the core tube. The advantage is that it makes a clean and square cut and does not generate plastic shavings the way a saw cut would. For thin walled plastic tubes, the pipe cutter must be paired with a backing cylinder to prevent the plastic tube from compressing during the cut. The backing cylinder can also be used to close gaps in the sediment inside the tube.

+

Drive Rods

Made from a lightweight, stiff magnesium-zirconium alloy, CSD Facility drive rods provide a solid connection to direct-push soft sediment corers. Available in lengths of 1.5 m or 2 m.

+

Drive Rod Handle

For standard Livingstone/ Bolivia coring pipe wrenches are recommended (2, 3, or 4 wrenches spaced evenly around the drive rod) as handles for leverage in stiffer sediments. Pipe wrenches are low cost, widely available, can be placed in positions of optimal leverage for each person pushing/ pulling, and can be taken on and off of the rods quickly. The only disadvantage is that the teeth on the wrenches can leave burrs on the pipe wrenches. It is thus advisable to wear gloves and bring a file to remove them as needed. Avoid placing the pipe wrenches on the drive rod connectors. In fibrous sediments (e.g. peat) that require a sawing motion for the corer, a clamp style handle is available. Note that the sawing motion requires other modifications to the Livingstone system in order to be done without risking equipment loss.

+

Electric Capstan and Davit

Powered by a 12V marine battery, the capstan is capable of rapid deployment (135 ft/min line pull) of lightweight gravity corers and sampling equipment (up to 150lbs). It’s compatible with ¼” or ⅜” rope of unlimited length. The davit breaks down into 3 pieces for easy transport and can be mounted to the railing of vessels of opportunity.

+

Figure 8

A climbing figure 8 is a simple, non-abrasive tool that locks the piston cable while driving direct-push soft sediment corers.

+

Launch and Recovery System (LARS)

Portable frame for overboarding and deployment of Kullenberg corer and other heavy equipment from vessels of opportunity.

+

Livingstone Coring Tower

The Livingstone Coring Tower uses a ratcheting winch to provide consistent mechanical advantage for pushing and pulling during direct-push soft sediment coring. These towers are owned by several community scientists. Contact CSD Facility staff to coordinate access.

+

Livingstone Strike Plate and Slide Hammer

The Livingstone corer can be paired with a slide hammer and strike plate to add percussion to assist with driving the corer. The strike plate can be added at any joint in drive rod string, but percussive strikes are best transmitted to the core tube when used at the joint just above the corer. The ~8kg hammer is ~7cm Ø x 40cm long and designed to fit inside a standard 10cm Ø casing if needed.

+

Livingstone Extruder

A simple ratcheting winch used to extrude soft sediment cores from a Livingstone corer.

+

Slicer Extruder

A robust extruding device for soft sediment surface corers that allows easy and precise sub-sampling in the field.