BME PhD student helps design wearable arthritis device and create start-up

Claire Kaiser knew she wanted to work at a medical device company, but never imagined she’d have the opportunity to help form one as a second-year biomedical engineering PhD student.

“It’s the best of both worlds,” Kaiser says of her experience with the University of Minnesota. “I’m doing lab work, publishing papers, and answering important biological questions, plus I’m getting hands-on experience creating a medical device start-up.”

The ample opportunities to enter the medical device industry are part of what attracted the Seattle native to the Midwest when she began exploring PhD programs after completing her undergrad at the University of Rochester in New York. She ultimately chose the University of Minnesota, feeling the nationally recognized program and the people there could best set her up for success.

“Everyone here is really committed to helping you learn, grow, and succeed,” Kaiser says of the faculty, labmates, and fellow students. “I’ve felt that since the first time I visited—it’s just a very supportive network.”

Conducting cutting-edge research

When Kaiser began the program, she, like the rest of her classmates, underwent a rotation of three faculty labs. She ended up selecting the SONIC Lab, directed by Professor Hubert Lim, and quickly jumped in on one of their studies.

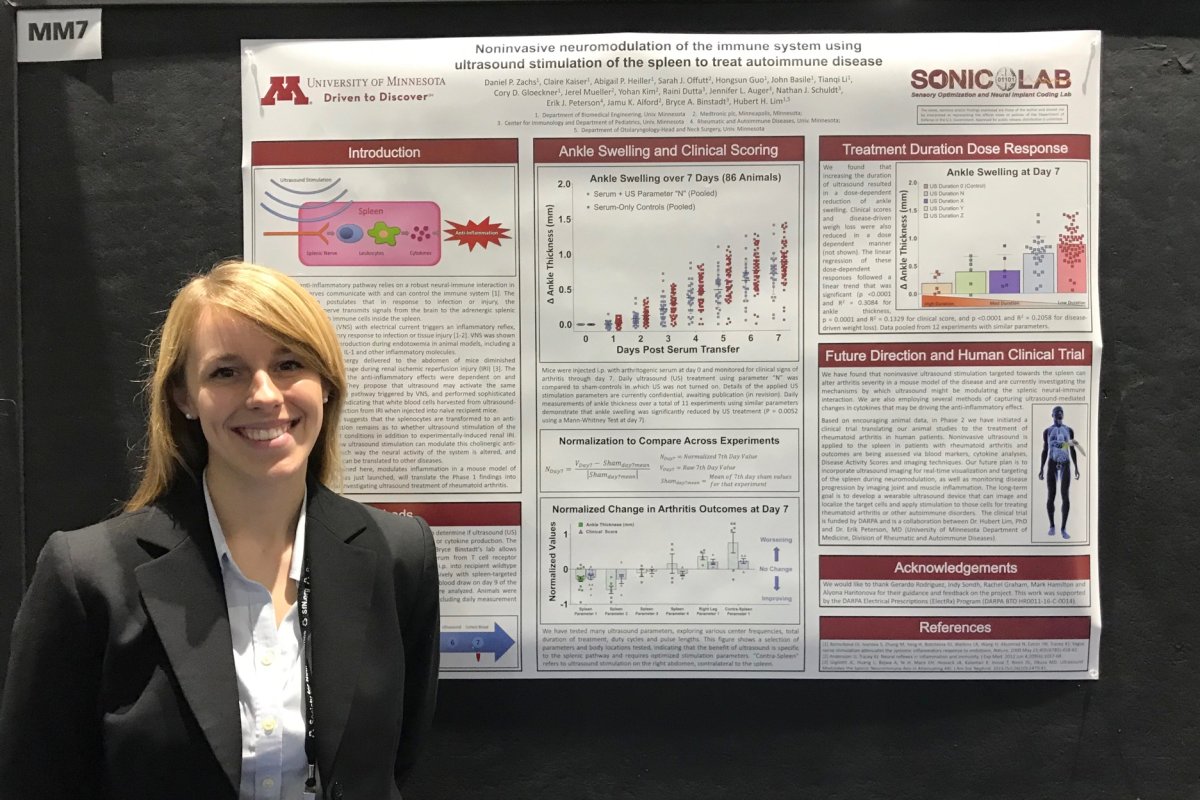

In partnership with Medtronic and U of M’s Dr. Bryce Binstadt, Prof. Lim’s lab had begun investigating ultrasound stimulation as a potential treatment for inflammatory arthritis. Biomedical engineering researcher and lab manager Daniel Zachs—a key driver of the study—trained Kaiser on the treatment regimen, and before long she was off conducting real research under Zachs’ direction.

Nature Communications published the lab’s findings (with Kaiser as a co-author), which showed that daily ultrasound stimulation of the spleen in mice with inflammatory arthritis resulted in significantly less joint swelling.

“The hope is that this could be a new, noninvasive way to deliver treatment,” explained Kaiser.

The study’s findings are an important first step for creating a new treatment option for the million-plus Americans who suffer from rheumatoid arthritis. The condition is typically treated through medications, which have a range of side effects.

To better understand how the treatment will affect humans, the lab team has since started a clinical trial with Dr. Erik Peterson of the U of M’s Medical School, located next to the Department of Biomedical Engineering.

“This whole experience has been really cool because I get to see the full lifetime of this research,” says Kaiser.

Creating a medical device

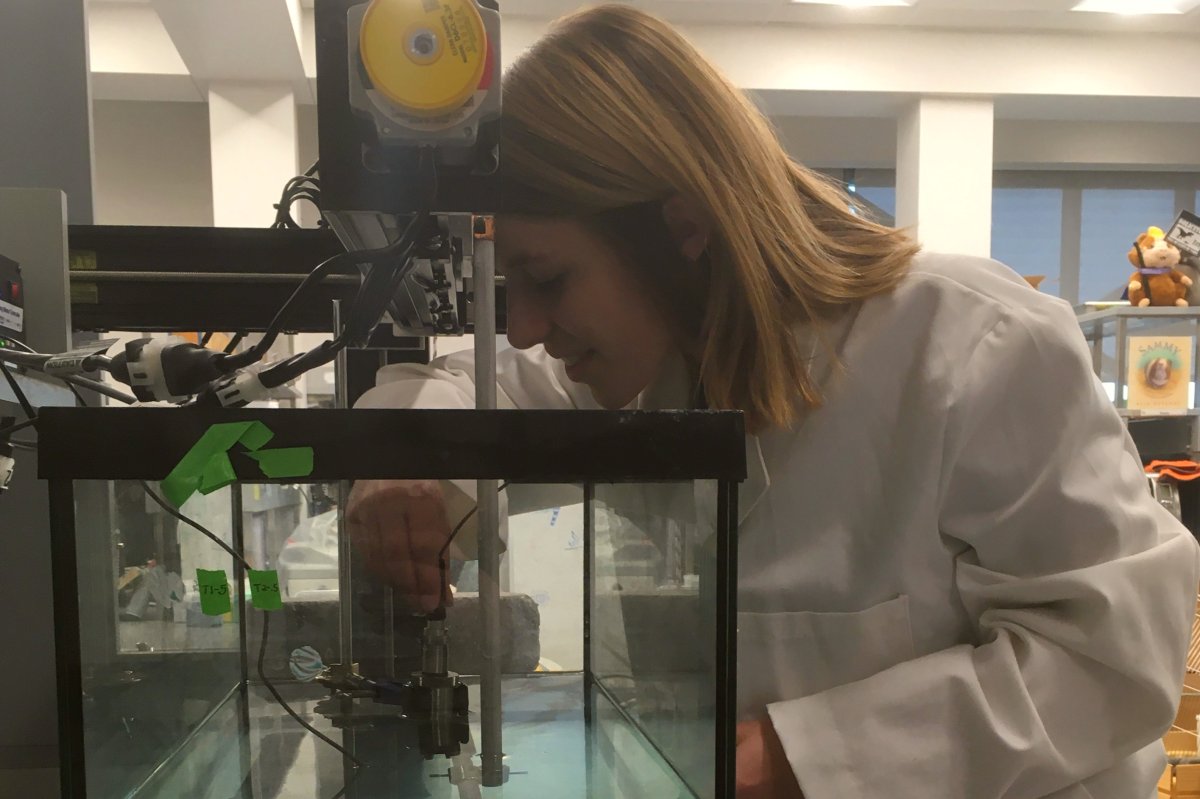

The ultrasound technology currently on the market isn't completely suitable for use in Kaiser and Prof. Lim’s new treatment, so they started working with an industry partner to create a new medical device. Now they’re creating a wearable ultrasound device for treating people with rheumatoid arthritis as well as other pain and autoimmune conditions.

The effort began when Kaiser received a prestigious MnDRIVE fellowship as a second-year PhD student. The fellowship funds University of Minnesota researchers who team up with industry or community partners to accelerate high-impact research.

The industry connection came through Kaiser’s mentor, Prof. Lim, who introduced her to Anuj Bhardwaj of The Ultran Group. The company manufactures ultrasound transducers (devices that send ultrasound waves into the body and receive the echoes)—exactly the kind of expertise Kaiser and team needed.

“Now I’m learning how to design a medical device,” says Kaiser. “I’m planning which capabilities it needs to have based on what our research found to be effective.”

Kaiser created and ran computer models of the wearable device that Bhardwaj’s team had fabricated. Then, Kaiser and Bhardwaj worked together to test the device’s ultrasound output in different ways and compare the results to the computational model she developed.

“It’s super rewarding to work on a device that could someday help people and increase their wellbeing,” Kaiser says. “I didn’t think I’d be able to have this kind of industry experience this early in my graduate school career.”

Building a start-up

The team’s efforts ultimately led Kaiser, Prof. Lim, and Bhardwaj—along with The Ultran Group’s Kashyap Patel—to create SecondWave Systems, a Minnesota-based company that aims to develop and commercialize the wearable device.

As a founding member of and key contributor to SecondWave, Kaiser has an opportunity to build something from the ground up. The endeavor has also given her insight into the business side of developing medical devices, creating real-world context for what she's learning in her business and technology courses.

For example, Kaiser was involved in efforts to submit a patent, which gave her first-hand insight into the regulatory process for putting devices on the market.

Kaiser also teamed up with Bhardwaj and Prof. Lim to write a successful grant application. They now have a $3.3 million Small Business Innovation Research (SBIR) award from the Defense Advanced Research Projects Agency (DARPA), which they used as seed funding for SecondWave.

The whole start-up experience has made the application of biomedical engineering come to life, Kaiser explains:

“I’m discovering first-hand what’s needed for a device to be feasible. I also have a better understanding of how to look at a problem from a wide range of perspectives—a biomedical engineer, a businessperson, a patient, and so on.”

Making connections

The Ultran Group and Medtronic aren’t the only companies Kaiser has interacted with. 3M is also an important partner in the device development efforts. And, since starting the PhD program, Kaiser has met people from many of the Twin Cities’ other 500-plus medical device companies.

“The medical device industry is everywhere here,” she says.

Opportunities have come through the department’s vibrant alumni network, events organized through the Graduate Women in Biomedical Engineering group, the Center for Neuroengineering, the Minnesota Innovation Corps, and even her ultimate frisbee league.

“Minnesota is a great place to be,” Kaiser says. “It’s so easy to transition from being a graduate student to working in a job; you don’t even have to move.”

Forging forward

As Kaiser embarks on her PhD project, she’ll be drawing from both the academic study and the start-up experience. Specifically, she’ll be investigating the wearable ultrasound device as a new way of communicating with nerves and end-organs, and modulating their behavior.

“I’m trying to understand why the treatment works,” she says. “Biologically, what’s the pathway that is activated?”

After graduation, Kaiser sees herself working in industry by continuing to pursue the start-up. She adds:

“Ultimately, I want to help people by changing the way diseases are treated. The medical device industry, especially here in Minnesota, does a great job enabling that.”