S50 - Rock and Machine Shop

Introduction

The Department of Earth and Environmental Sciences hosts a fully equipped machine shop and self-service rock processing facility, located in John T. Tate Hall, Room S50. This facility is available to trained users only. All users must comply with safety training and facility procedures, including usage of the S50 User Google Calendar and sign in sheet.

New users interested in using the Rock Processing Facility must contact Christian Teyssier (teyssier@umn.edu) to coordinate safety and procedural training before receiving access. Users are generally responsible for providing any consumables they may need and should discuss their needs during training.

Equipment available for use is detailed below. Standard operating procedures (SOP) and detailed safety information are available in the accompanying links.

Tile and Trim Saws

This facility contains two commercial-grade tile and trim saws- an MK-101 high-speed tile saw (10” wet cutting diamond blade) and a Highland Park trim saw (10” wet cutting diamond blade). Saws are operated with an on/off foot pedal and are capable of accommodating a wide variety of sample sizes. Proper eye and ear protection are required at all times. Water-resistant vinyl work aprons are available for use.

S50 Saws SOP

Crushing and Pulverizing

A variety of tools are available for reducing trimmed rock samples. Manual options include a steel plate and rock hammers for coarse splitting, and a manually operated tabletop splitter.

A BICO Braun WD heavy duty Chipmunk jaw crusher can reduce sectioned samples (ideally < 2 in3) to 1/16”-5/8” chips.

Further milling and pulverizing is accomplished with a BICO Braun V-Belt Pulverizer (“disc mill”) equipped with hardened iron grinding plates. The reduction size is finely controllable; powders as fine as 150-200 mesh size are achievable. Lab groups with specialized applications (e.g., trace element analyses), or who anticipate heavy and prolonged use of this machine may be required to invest in personal grinding plates for the pulverizer. These are available in a variety of materials (including ceramic). Please discuss your needs with S50 lab managers.

A Donaldson Torit VS-1200 dust collector is available for various applications and is required during operation of the disc mill.

Crushing and Pulverizing SOP

Drill Press

A 20” Clausing variable speed drill press (Model 2277) can produce small rock cores and is available for other applications. Users typically need to provide their own drill bits for their application. Table height can be manually adjusted to accommodate a wide range of sample sizes. Repositionable clamps aid in securing samples to the work surface.

Drill Press SOP

Thin Section Making

The facility has thin section making equipment. In most cases, users will need to provide their own epoxy or adhering medium. Limited glass slides are available. A spring-loaded jig is available for curing rock billets to slides.

Lapidary wheel: A lapidary wheel (UKAM Smart Cut) with 12” diameter magnetic steel plate and variable speed (0-900 RPM), central spindle coolant (water) feed is available

for polishing of flat rock samples (~3” hand sample size and smaller). General use grinding pads (60 and 260 mesh diamond bond disks; 400-600 and 900-1,200 mesh resin bond disks) are available; individual users or groups may also provide their own polishing pads.

Thin section machine: A Struers DiscoplanTS thin section machine equipped with automatic feed water pump and vacuum system can be used to produce standard thin sections from standard size rock chips bonded to glass slides. The instrument is equipped with an 8” diameter, 1.0mm thick high-speed diamond saw blade used to trim excess rock material from glass slides, a 70µm roughness diamond cup wheel for final grinding down of the sample close to final standard thin section thickness. The thin

section machine is equipped with a 10µm-increment precision dial for progressive grinding.

Users requiring further fine polishing (<15 um) for microprobe, SEM, EBSD applications are referred to referred to specific labs based on the application (e.g., STAMP, RAMP, EPMA labs).

Thin Section Equipment SOP

Peripheral Equipment

- Sand blaster: A commercial-grade sand blaster is available for general use (particularly useful for cleaning pulverizer and chipmunk crusher plates).

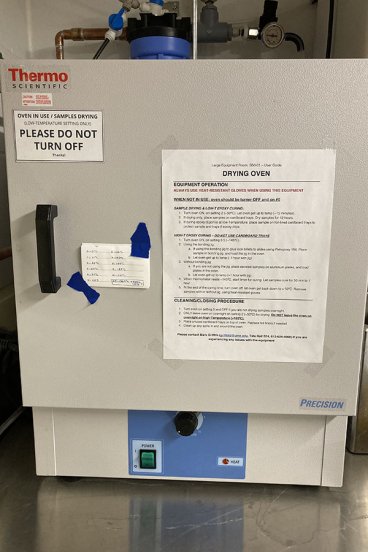

SandBlaster: Commercial-grade sand blaster for general use - Low-temperature drying oven: A Thermo Fischer Precision CP gravity convection oven is available for sample drying and curing up to 210ºC.

- Sonicator: A general-purpose sonicator is available for cleaning samples as large as 4x2x1”.

- DI water: Deionized water is available.

Oven: Thermo Fischer Precision CP gravity convection oven for sample drying and curing up to 210ºC.

Peripheral Equipment SOP

Machine Shop

A variety of heavy machinery for fabrication and other projects (e.g., lathes, miter saws, drill presses) are managed by Mark Griffith, Department Laboratory Machinist and Building Manager. Inquiries about equipment specifics and usage can be made via email at (griff062@umn.edu).